1325 ATC CNC Router Machine Details

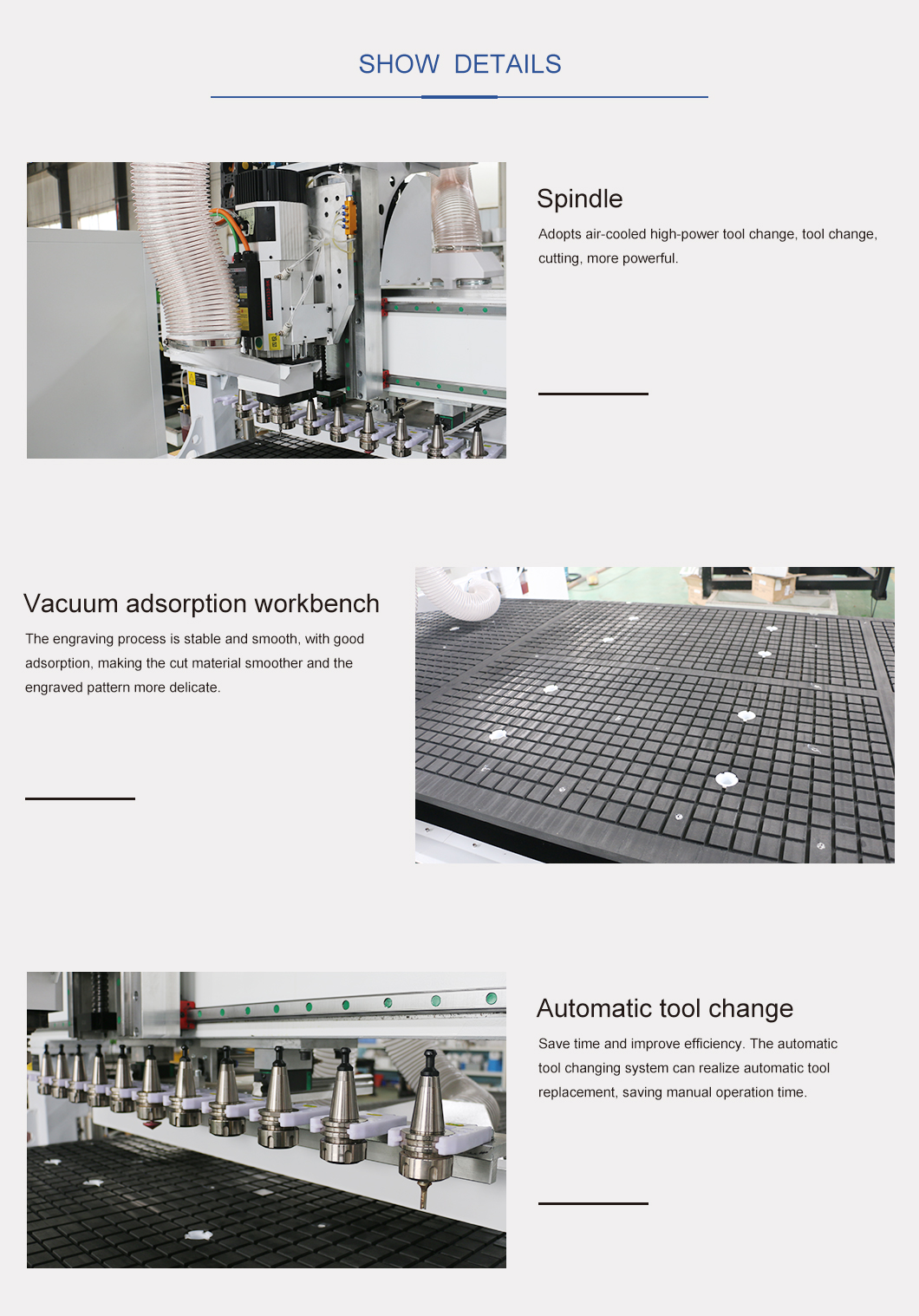

1.Adopts air-cooled high-power tool change, tool change, cutting, more powerful.

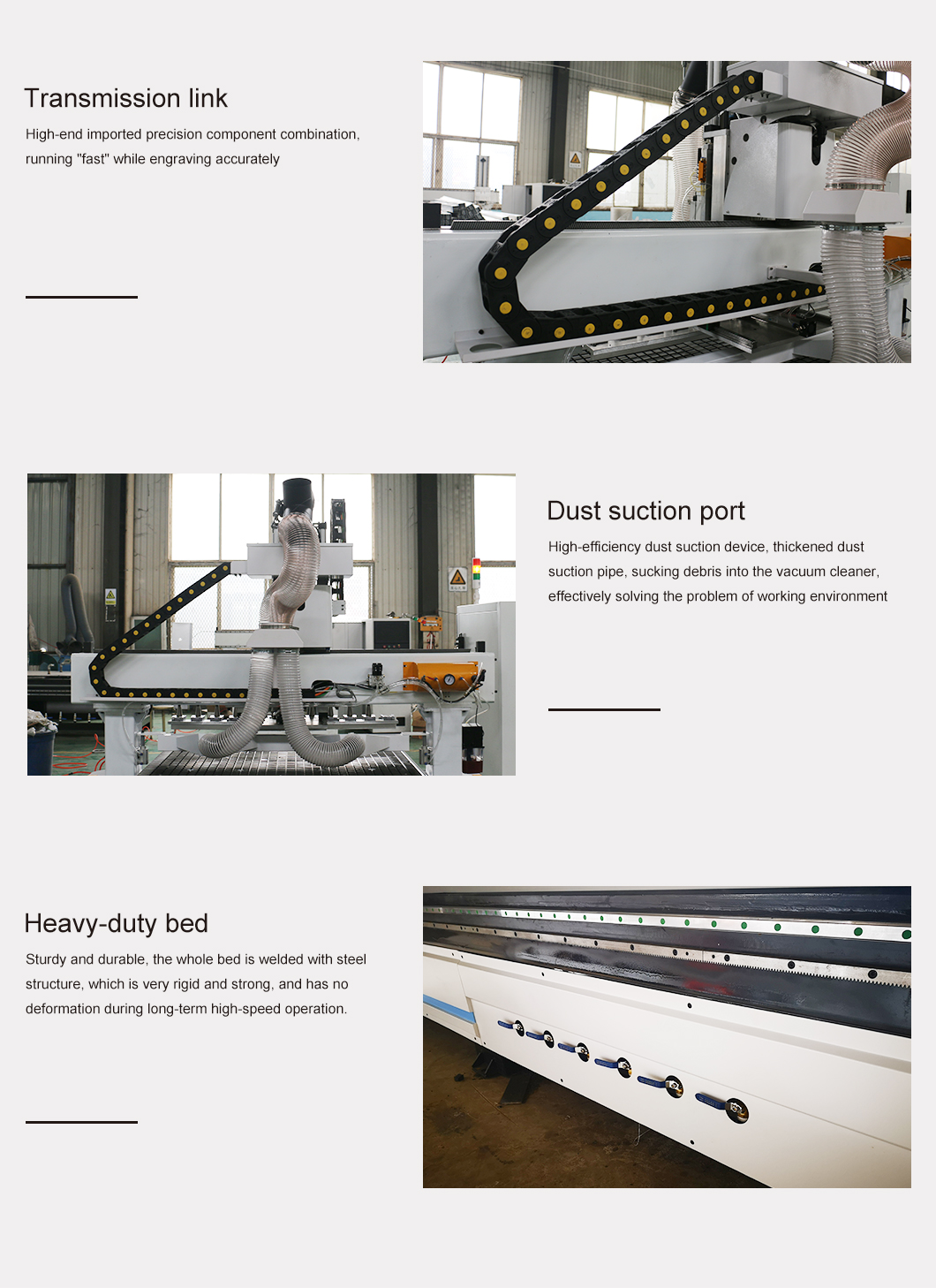

2.Vacuum adsorption workbench:Adopts a double-layer porous table with a reasonable structure and strong adsorption. The body is rigid and the workbench structure is stable.The engraving process is stable and smooth, with good adsorption, making the cut material smoother and the engraved pattern more delicate.

3.Electric oil injection system:Simple operation, intelligent digital display safety alarm. The automatic oiler can ensure the lubrication of the sliding screw guide rail according to the time.

4.Automatic tool change:Save time and improve efficiency. The automatic tool change system can realize the automatic replacement of tools, saving the time of manual operation and greatly improving work efficiency

5.The control system adopts well-known brand electrical components, with very stable quality, specially used for furniture production.

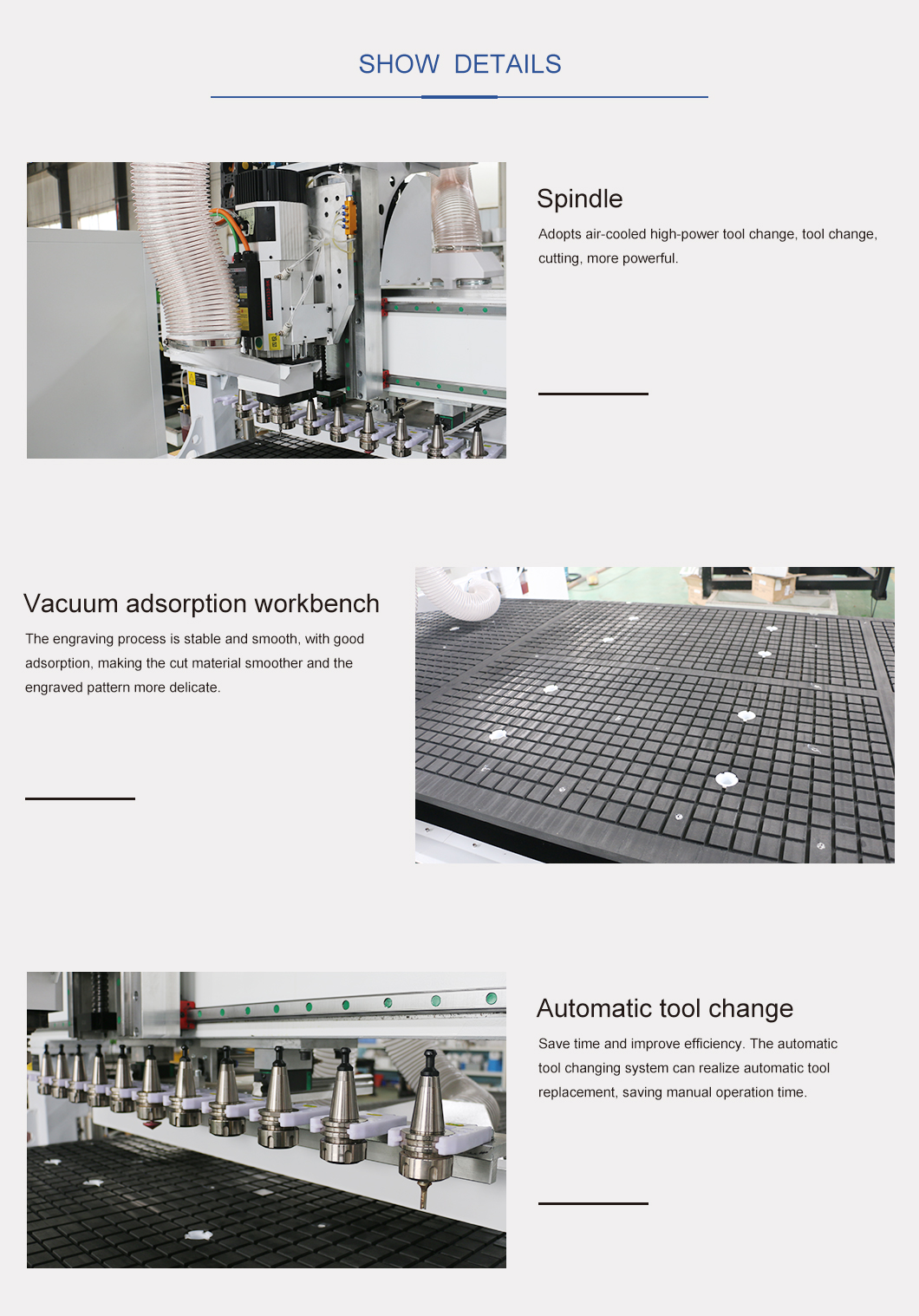

6.Transmission link:High-end imported precision parts combination, running "fast" while engraving with precision.

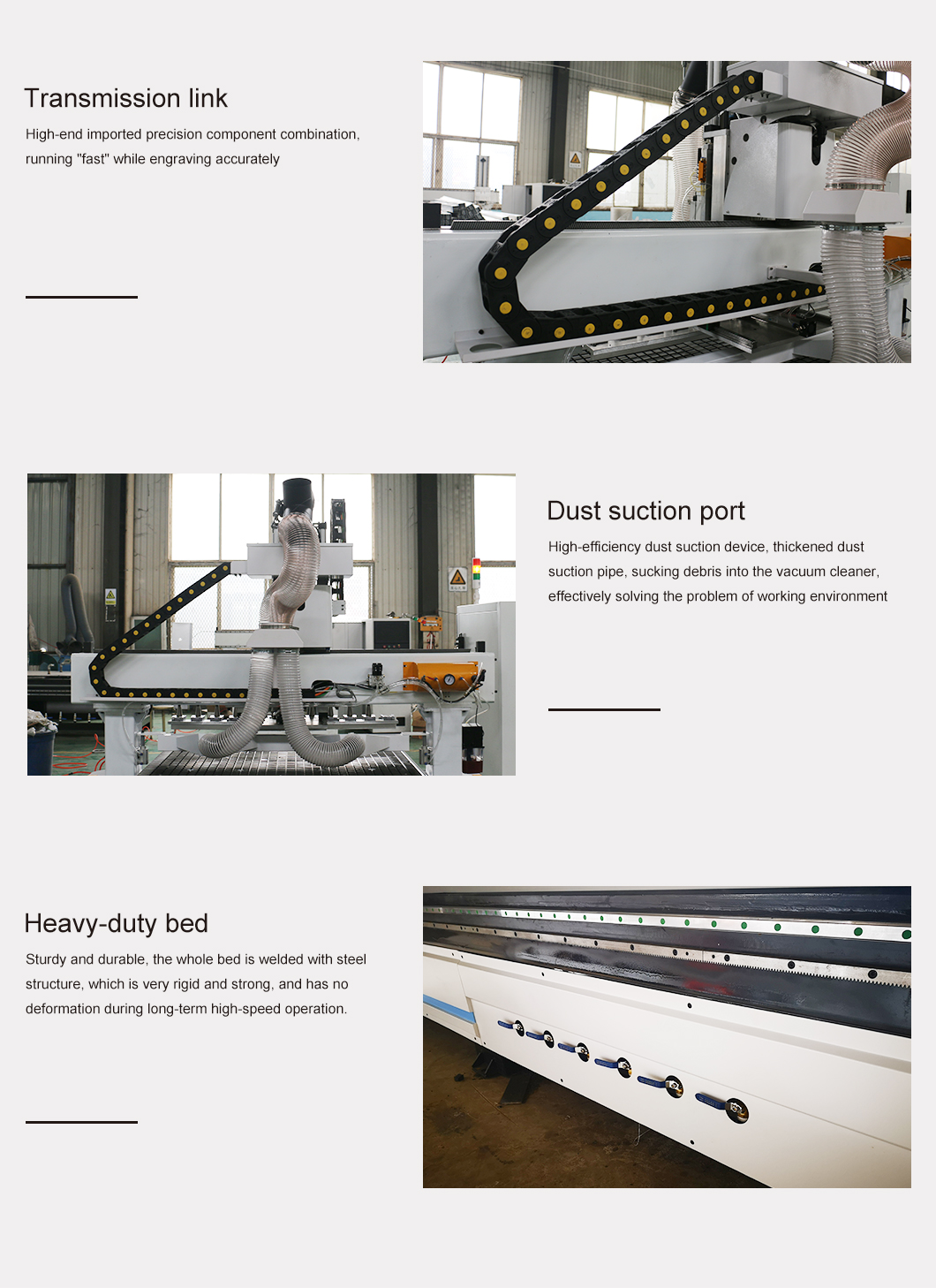

7.Heavy-duty bed:Sturdy and durable: The whole bed is welded with steel structure, strong stiffness, strong strength, long-term high-speed operation without deformation. The gantry movement strengthens the workbench, old and sustainable.

8.Dust suction port:High-efficiency dust suction device, thickened dust suction pipe, sucking debris into the vacuum cleaner, effectively solving the problem of working environment.

1325 ATC CNC Router Machine Paramenters

| | AC380V 50HZ 3HP three-way four-wire | | high-precision linear 25 square rails |

| | | | |

| | XY50000mm/min, Z20000mm/min | | |

| | | | straight row 12 follow-up tool magazine ISO30 |

| | vacuum adsorption table 1260*2480 6 partitions 24 holes | | Taiwan Baoyuan MW2200 system |

| | heavy-duty double-layer unloading trapezoidal bed | | |

1325 ATC CNC Router Machine Details Images