CNC Tenon Machine Features

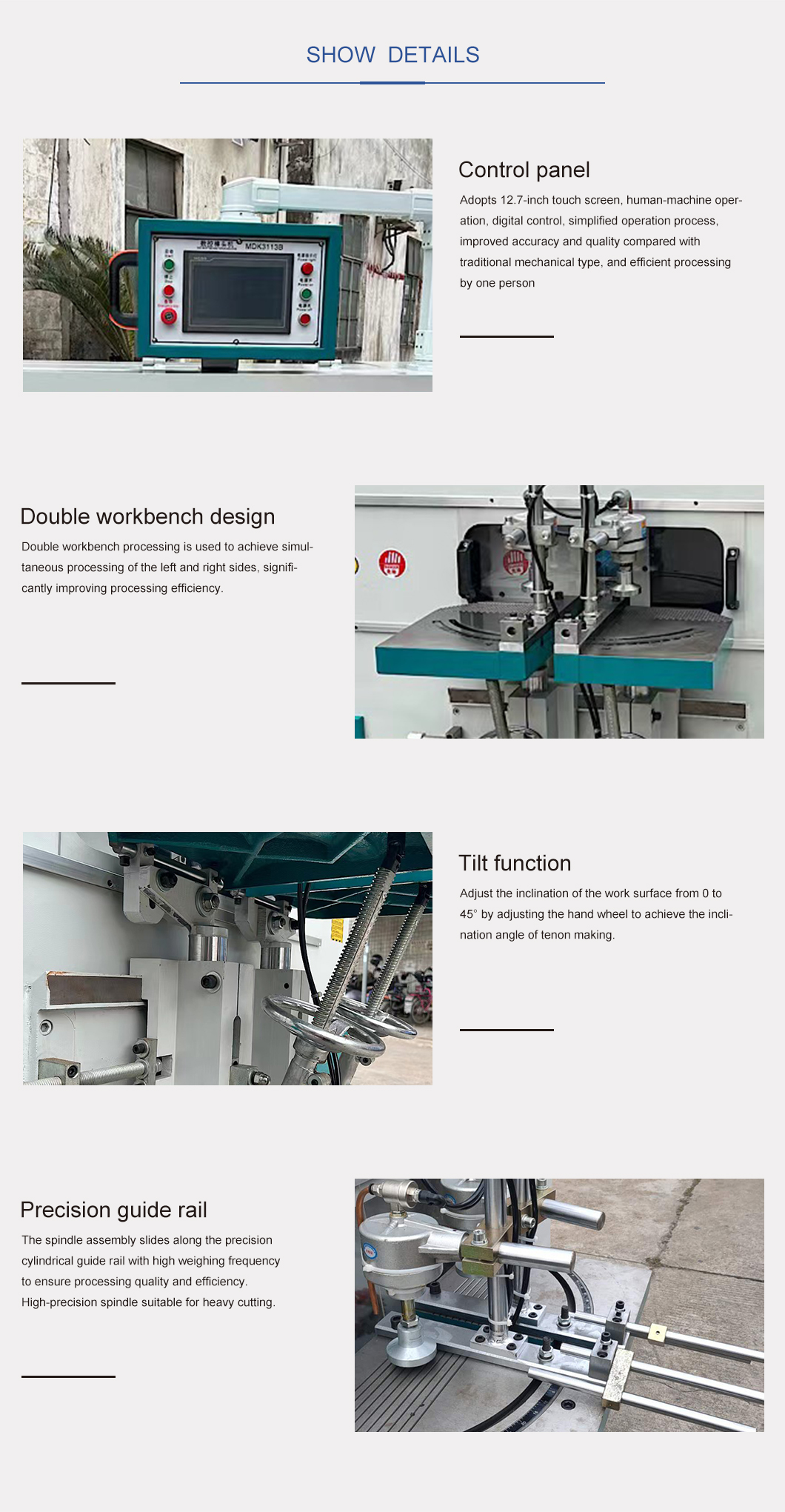

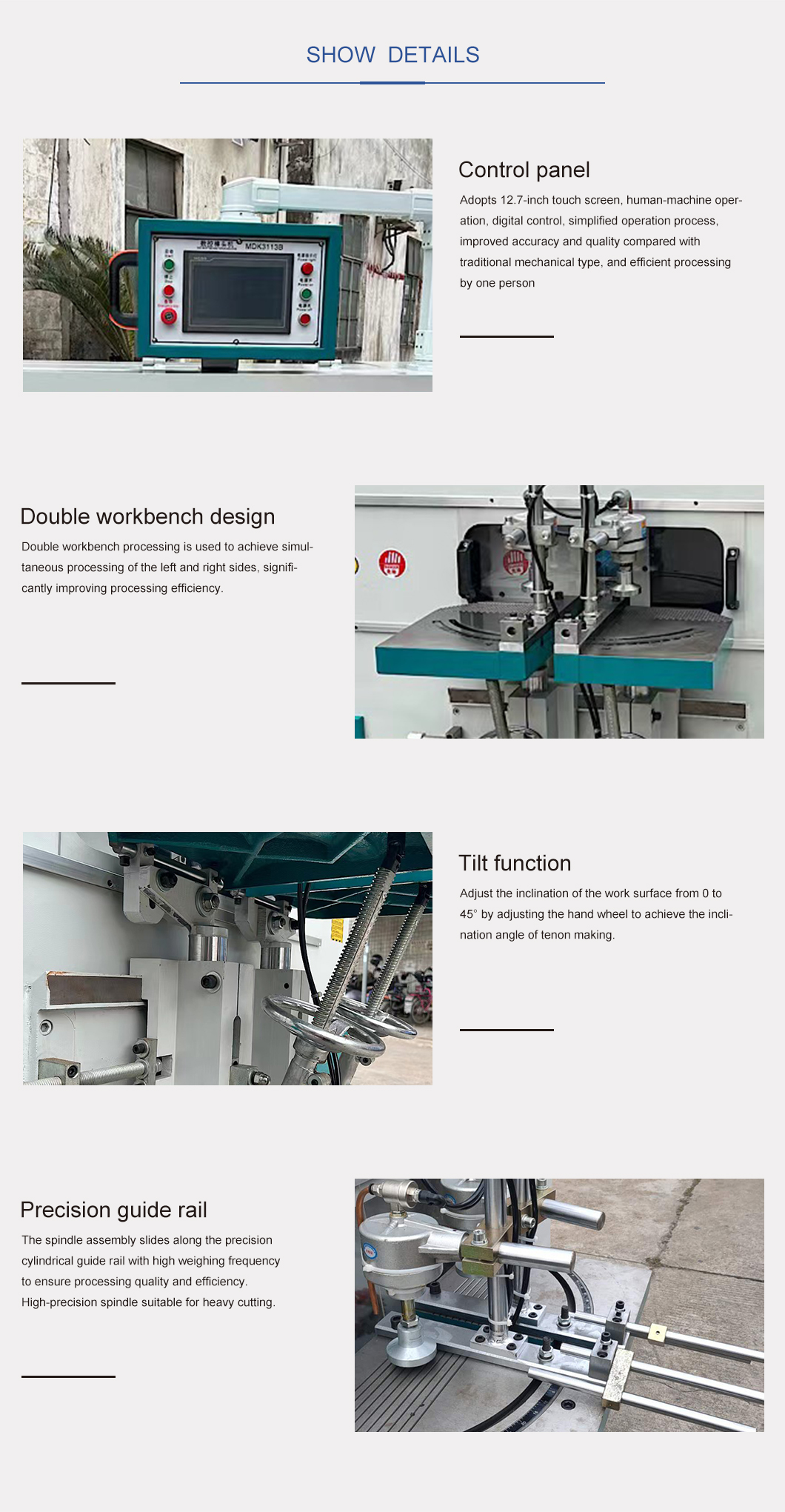

1.Control panel:12.7-inch touch screen,digital control, simplified operation process.

2.Digitally control the size and shape of the tenon to improve accuracy.

3.Multi-directional knife axis adjustment increases operational flexibility and safety.

4.Double workbench design, processing on both sides at the same time, improving processing efficiency.

5.Transmission system: Ball screw transmission is used to ensure high precision and durability.

6.Combined tenon cutters increase processing versatility.

7.Tilt function: Adjust the inclination of the work surface from 0 to 45° by adjusting the hand wheel to achieve the inclination angle of tenon making.

8.High-speed precision electric spindle is suitable for processing wood of different materials, ensuring processing accuracy and efficiency.

9.Precision guide rail: The spindle assembly slides along the precision cylindrical guide rail with high weighing frequency to ensure processing quality and efficiency. High-precision spindle suitable for heavy cutting.

10.Speed regulating structure: The unique speed regulating structure allows the speed of the spindle mortise machining to be adjusted to adapt to different processing needs.

11.Safety device: The machine is equipped with a transformer device to effectively protect the normal operation of electrical components during high-speed processing.

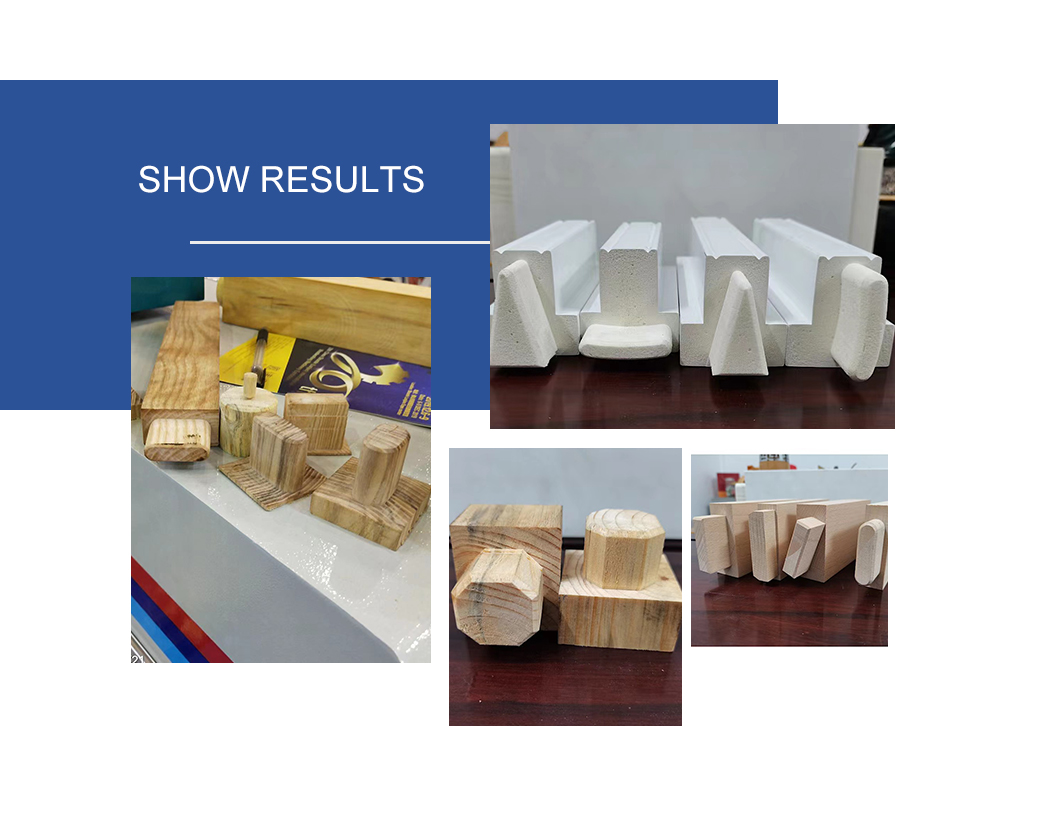

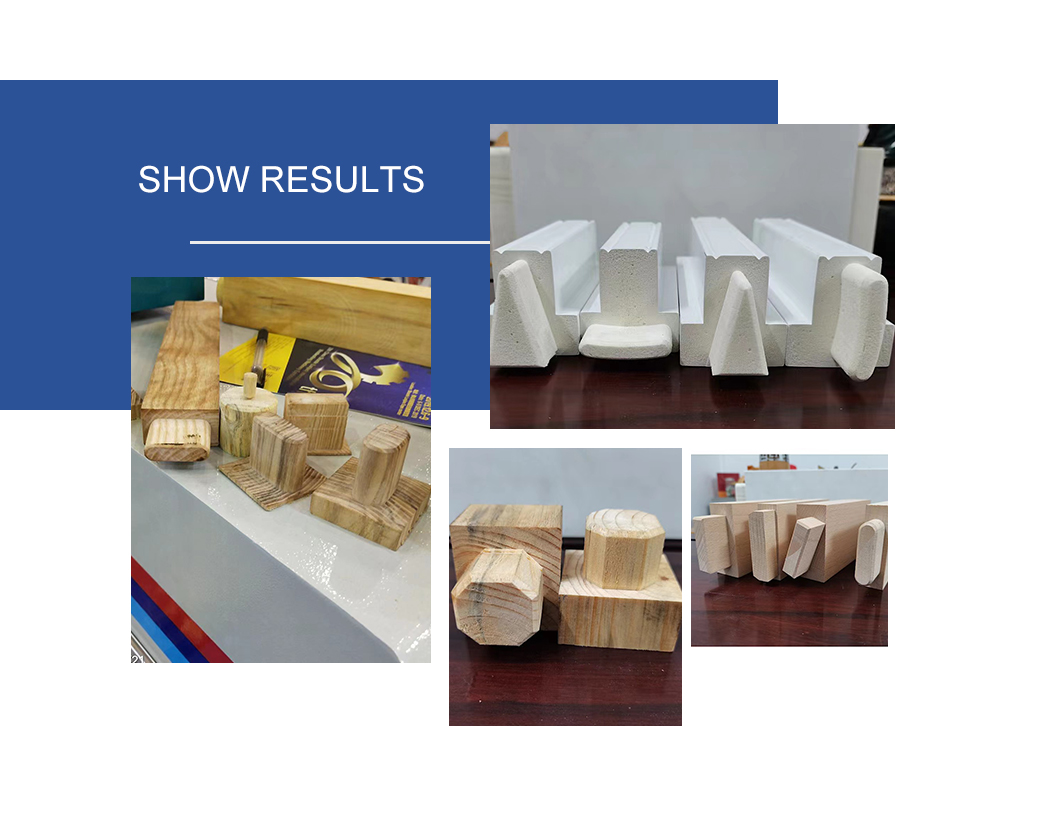

12.Wide applicability: suitable for tongue and groove processing of doors, tables, chairs and other products to meet diverse production needs.

CNC Tenon Machine Parameters

| | |

Maximum size of square tenon | |

Maximum diameter of round tenon | |

Max width of horizontal round tenon | |

Max processing width of vertical waist round tenon | |

| | |

CNC Tenon Machine Details Images