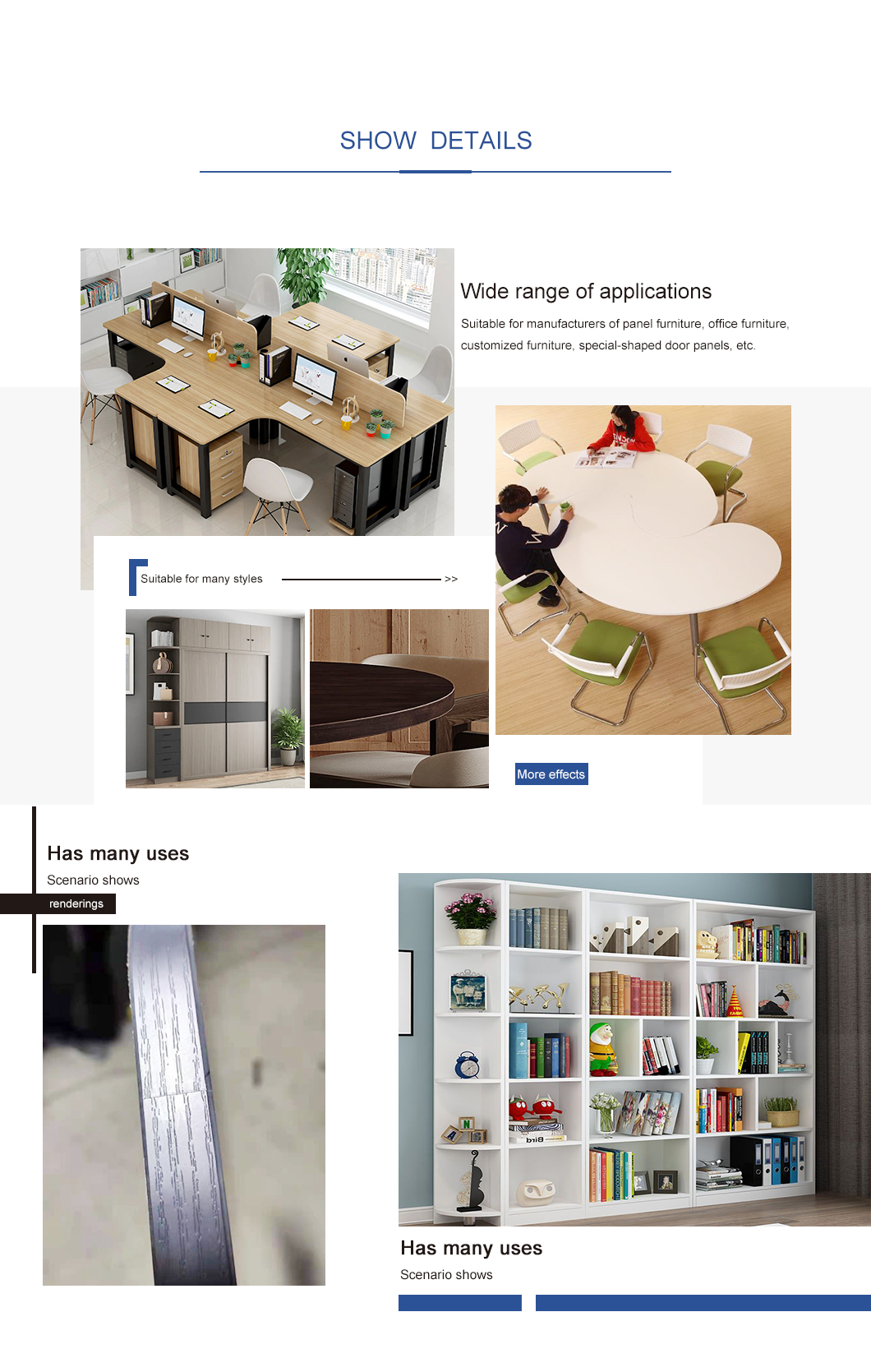

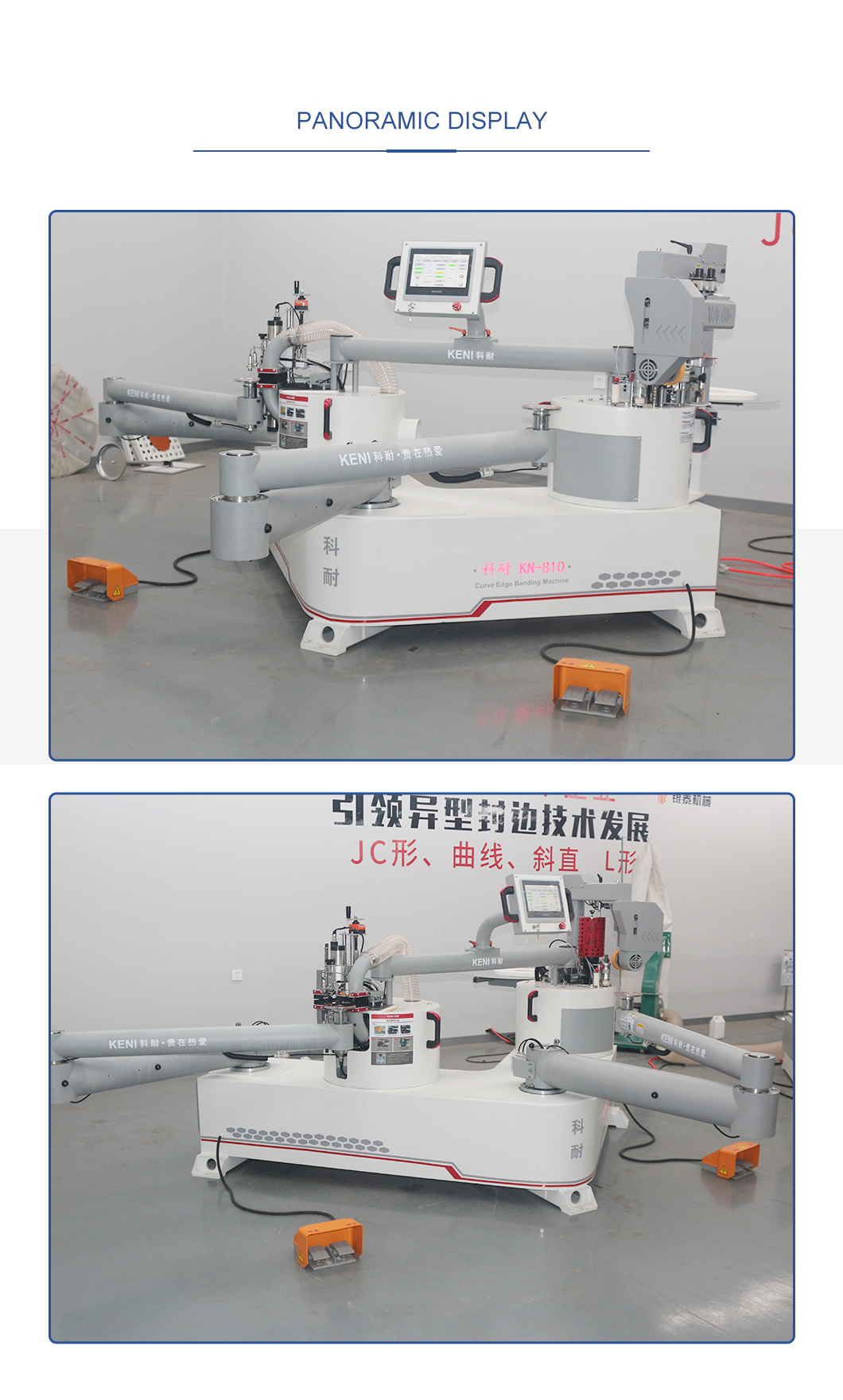

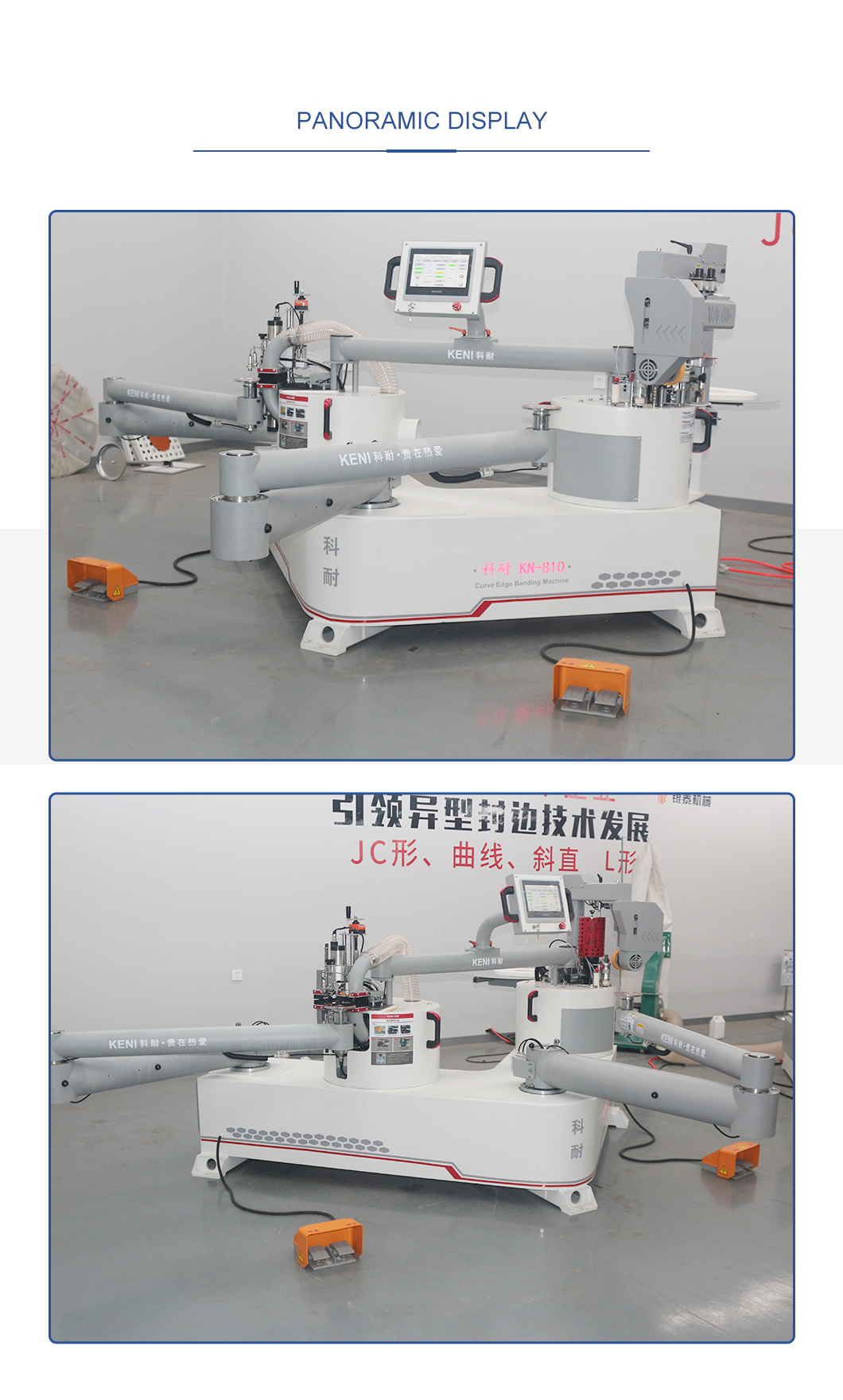

Double Stacked Arm Curve Edge Banding Trimmer Machine Advantages

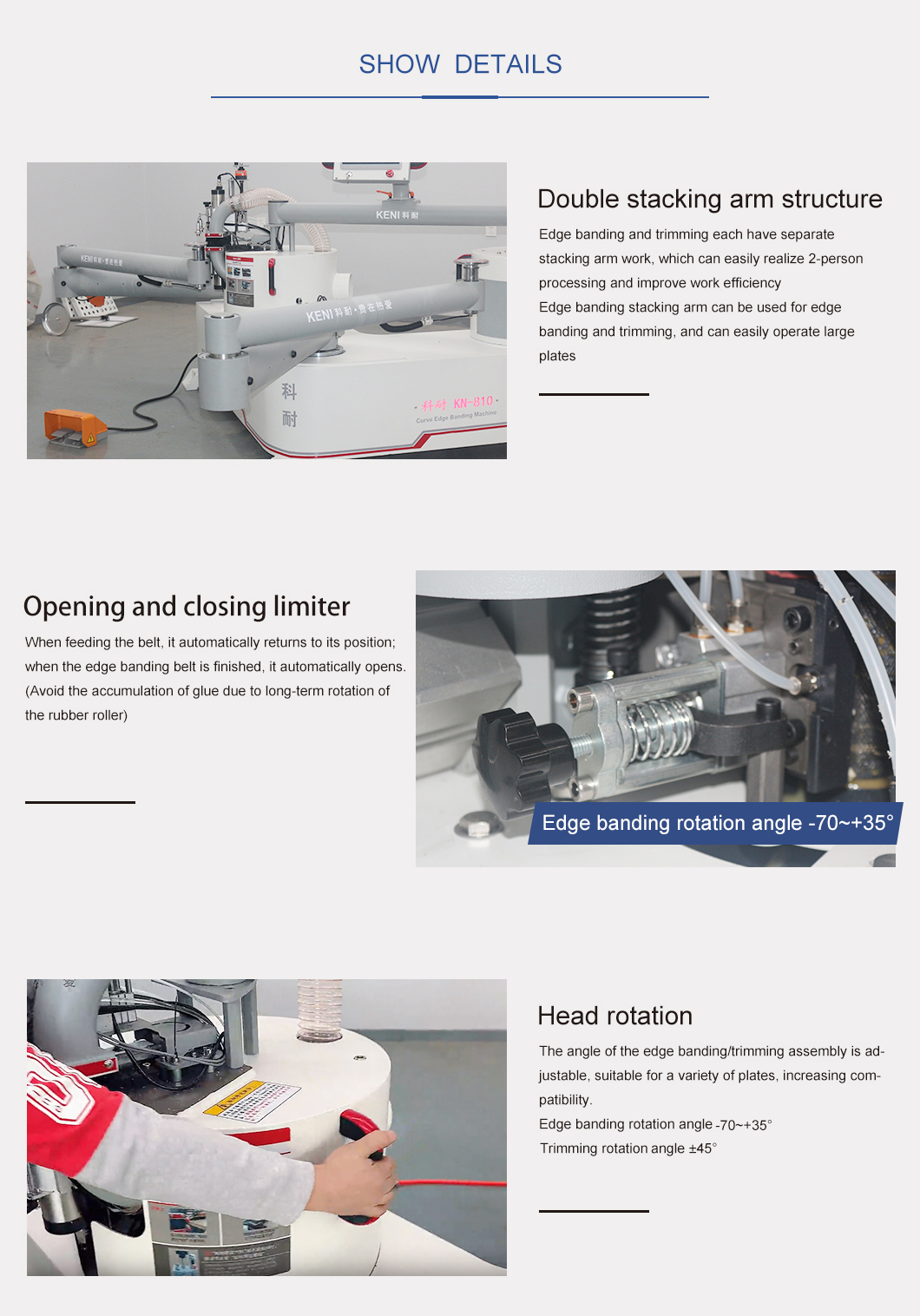

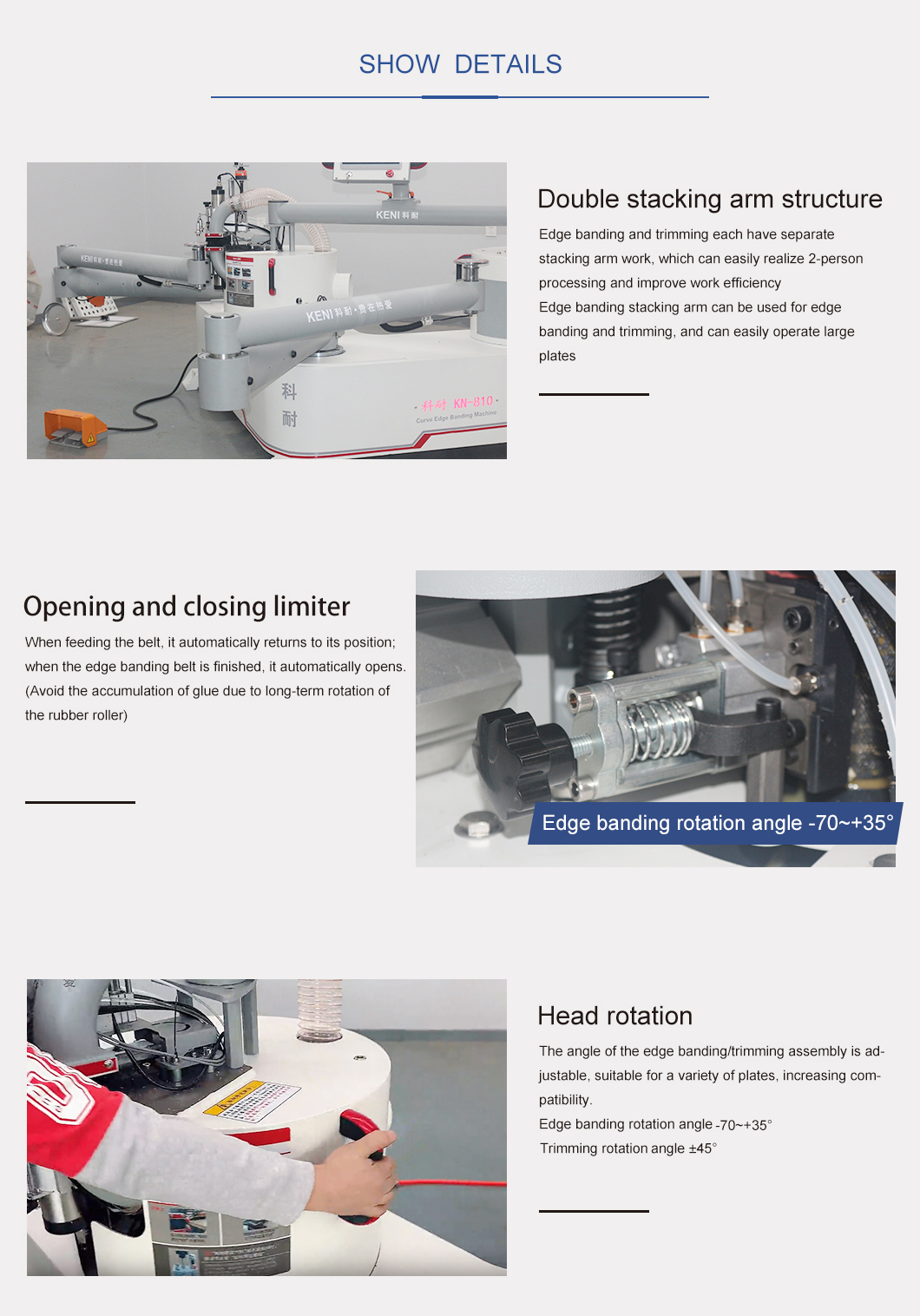

1.Opening and closing limiter/pressing strip assembly:When feeding the belt, it automatically returns to its position; when the edge banding belt is finished, it automatically opens. (Avoid the accumulation of glue due to long-term rotation of the rubber roller)

2.The angle of the edge banding/trimming assembly is adjustable, suitable for a variety of plates, increasing compatibility. Edge banding rotation angle -70~+35° Trimming rotation angle ±45°.

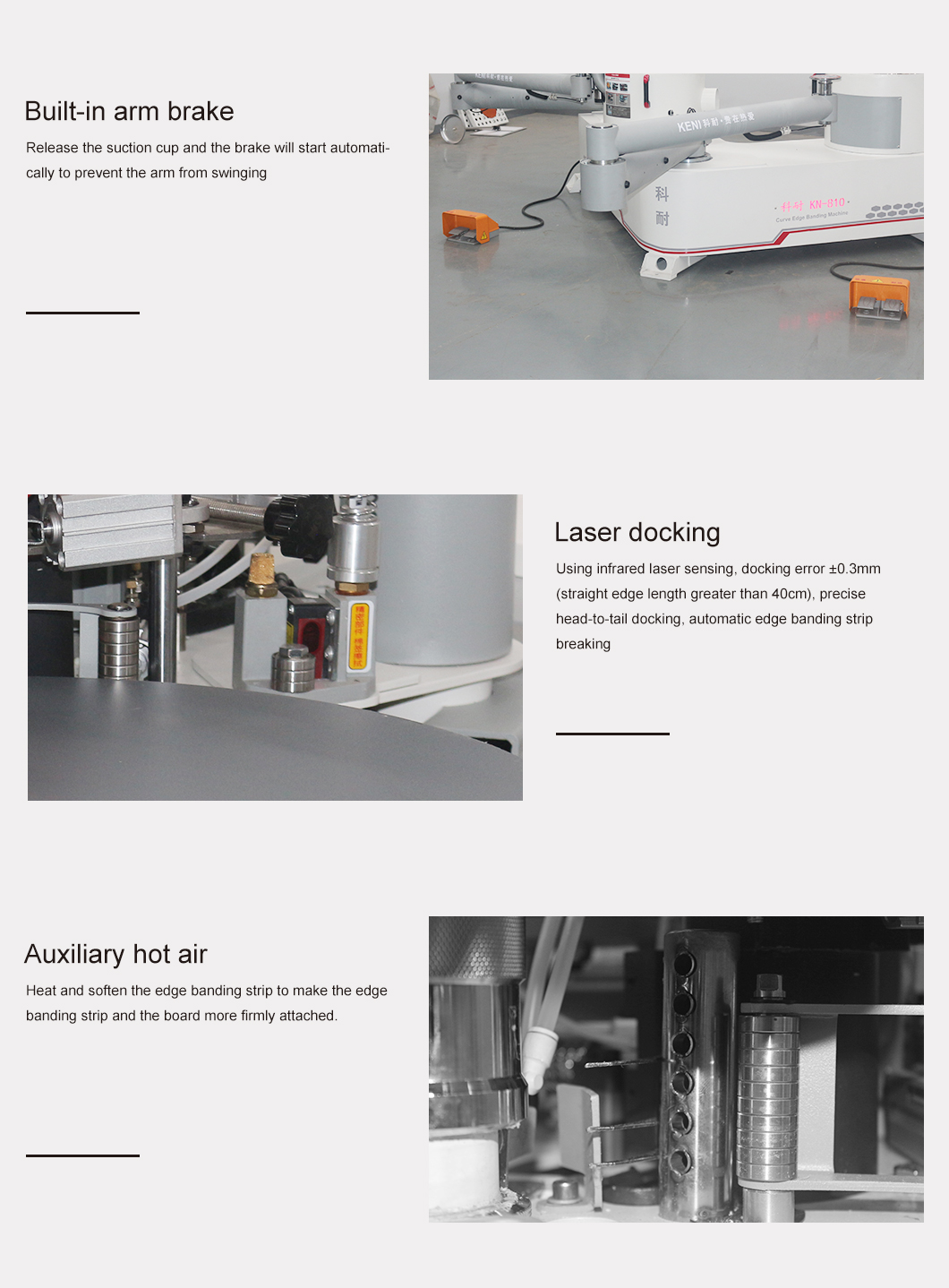

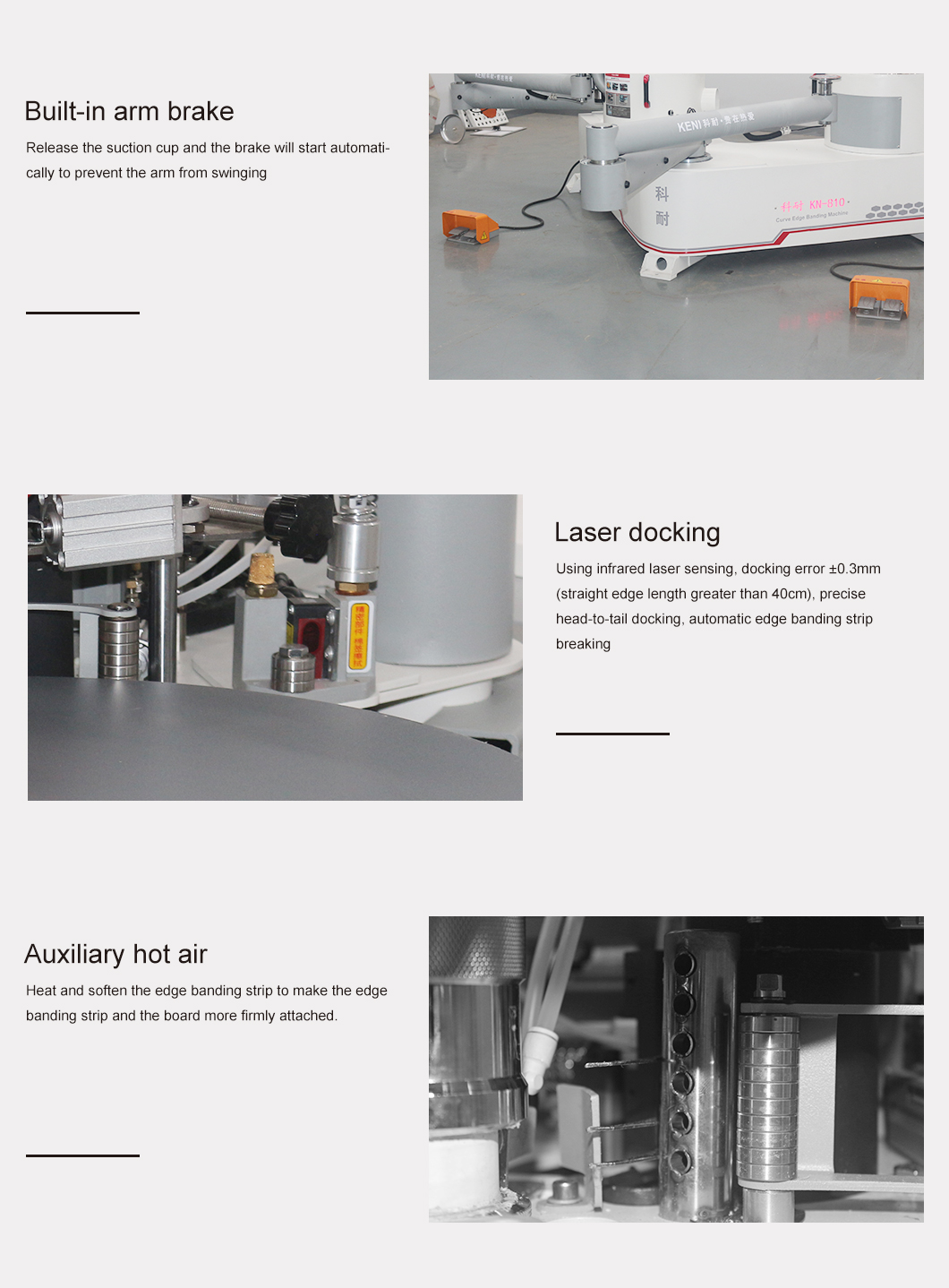

3.Built-in arm brake:Release the suction cup and the brake will start automatically to prevent the arm from swinging.

4.Auxiliary automatic feeding:Applicable to irregular plates such as round, oval, rounded rectangle, etc., free your hands for small plates.

5.Automatic acceleration and deceleration:Automatically decelerates when reaching a corner, allowing workers to turn the board easily.

Edge Banding

1.Laser distance measurement docking:Using infrared laser sensing, docking error ±0.3mm (straight edge length greater than 40cm), precise head-to-tail docking, automatic edge banding strip breaking.

2.Internal Teflon coating PUR, EVA dual-use upper glue pot can quickly dissolve glue, touch screen one-button glue discharge, simple and convenient.

3.Auxiliary hot air:Heat and soften the edge banding strip to make the edge banding strip and the board more firmly attached.

4.Standard secondary auxiliary pressing wheel:The edge banding strip and the board are pressed twice to increase the banding firmness.

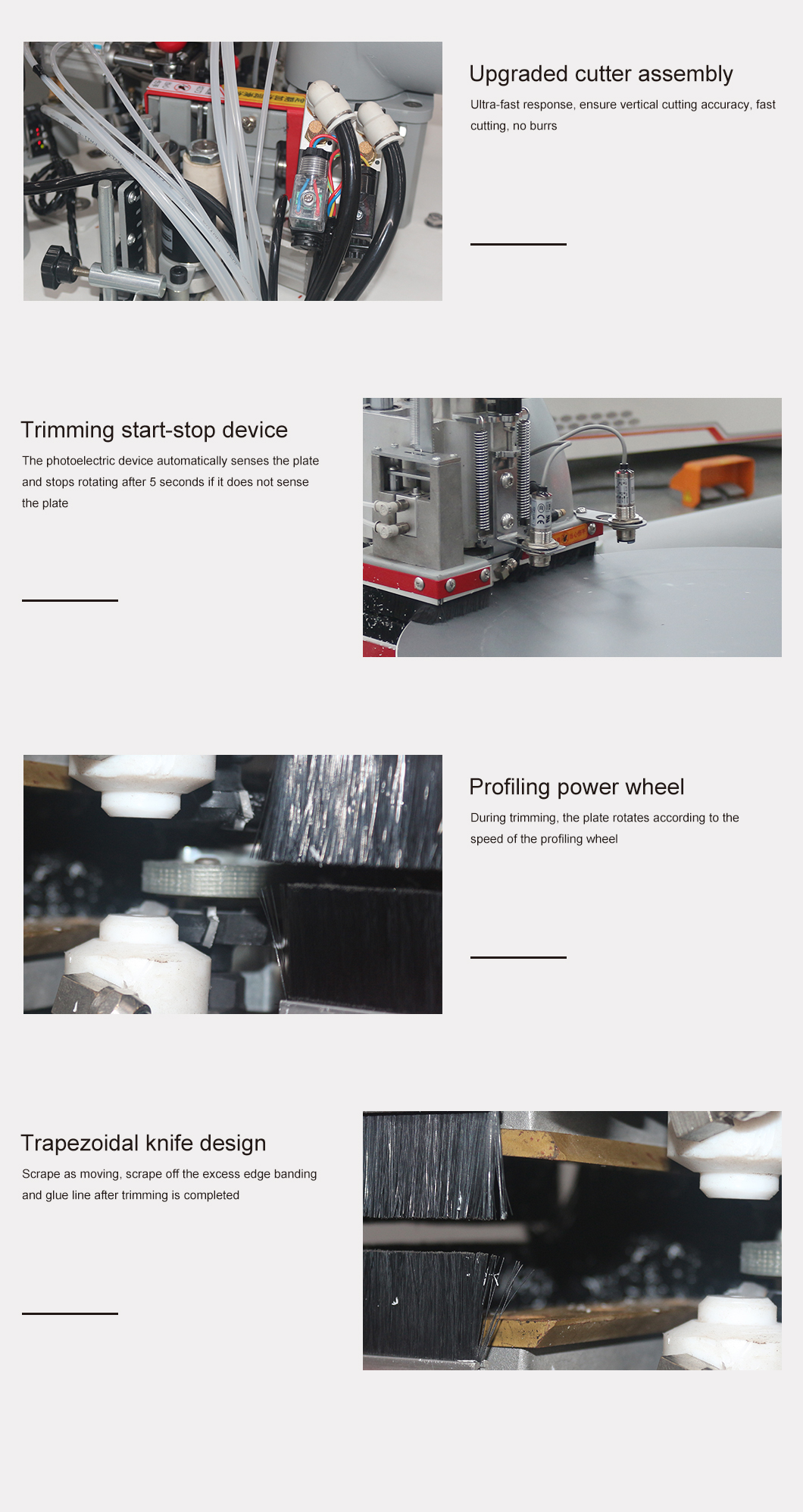

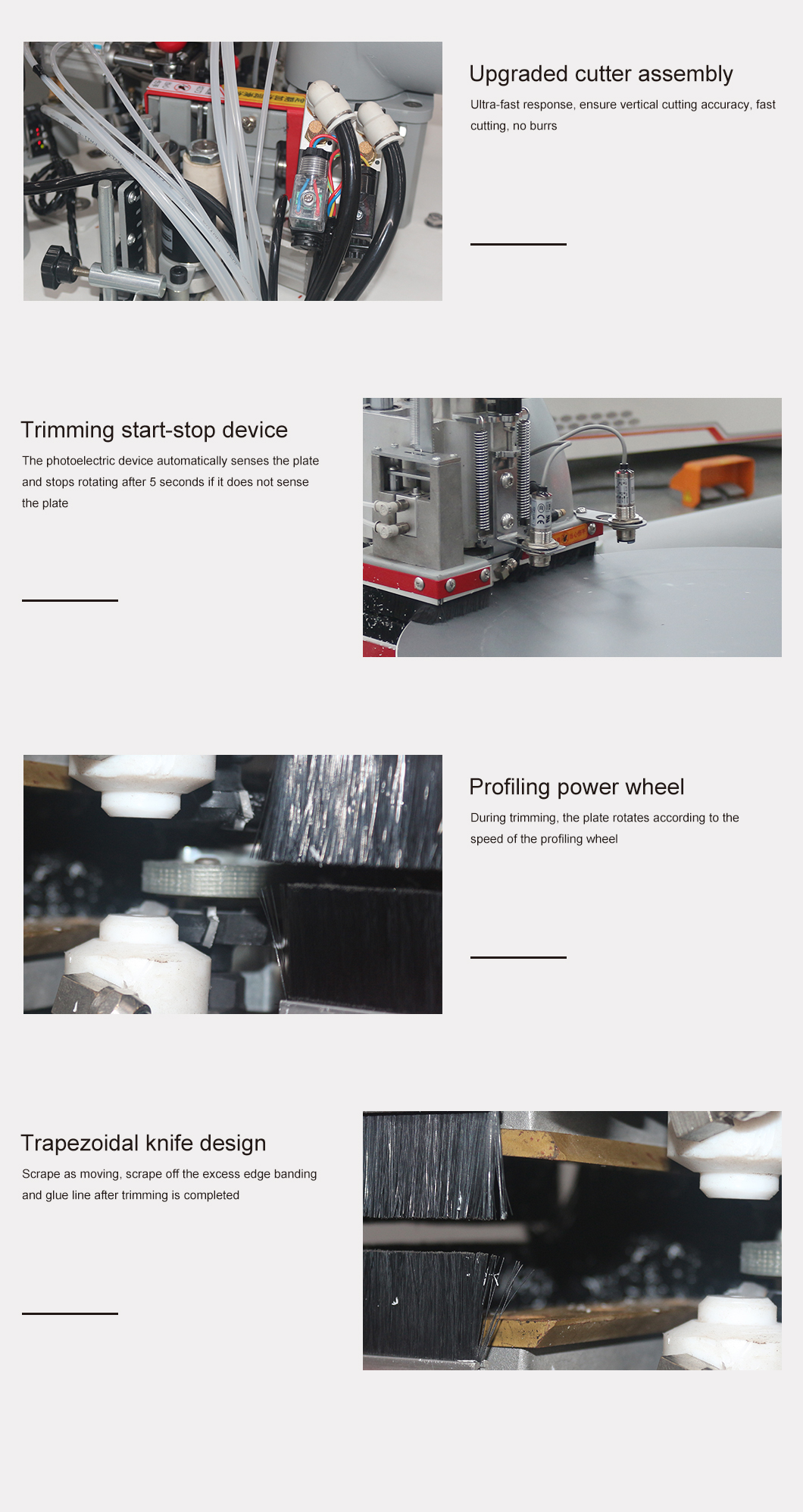

5.Upgraded cutter assembly:Ultra-fast response, ensure vertical cutting accuracy, fast cutting, no burrs.

6. Automatic spraying of glue remover:Avoid glue sticking at the bonding wheel and the pressure strip plate to ensure the edge banding effect.

7.Optional: Small workpiece operation platform.Suitable for small board edge banding.

Edge Trimming

1.Trimming start-stop device:The photoelectric device automatically senses the plate and stops rotating after 5 seconds if it does not sense the plate.

2.Profiling power wheel:During trimming, the plate rotates according to the speed of the profiling wheel.

3.Upper and lower trapezoidal knife design.Scrape as moving, scrape off the excess edge banding and glue line after trimming is completed.

4.Trimming cleaning device:Automatically sprays clean glue liquid, the spray can be adjusted.

Double Stacked Arm Curve Edge Banding Trimmer Machine Paramenters

| | 380V/three-phase four-wire/50HZ | | |

| | | | |

| | | | 0.5-3mm (related to the material of the edge) |

| | | | <14mm single-sided trimming, 14-70mm Upper and lower double trimming (related to trimming knife) |

| | | | ≥20mm (special operation can seal radius 4mm) |

| | | | |

| | | | |

| | | | |

| | | Edge sealing material types | PVC\wood veneer\melamine\plastic and other materials |

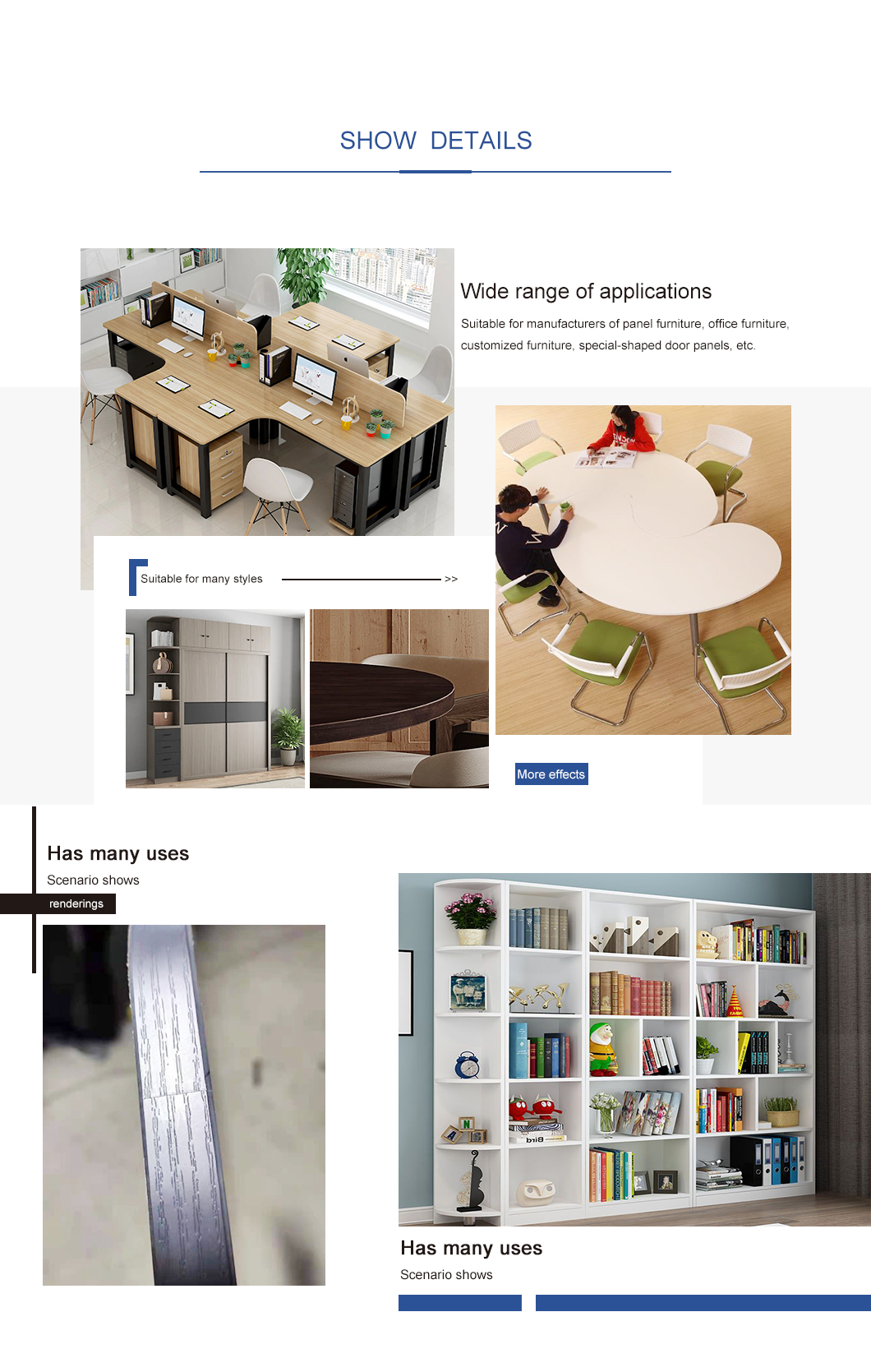

Double Stacked Arm Curve Edge Banding Trimmer Machine Details