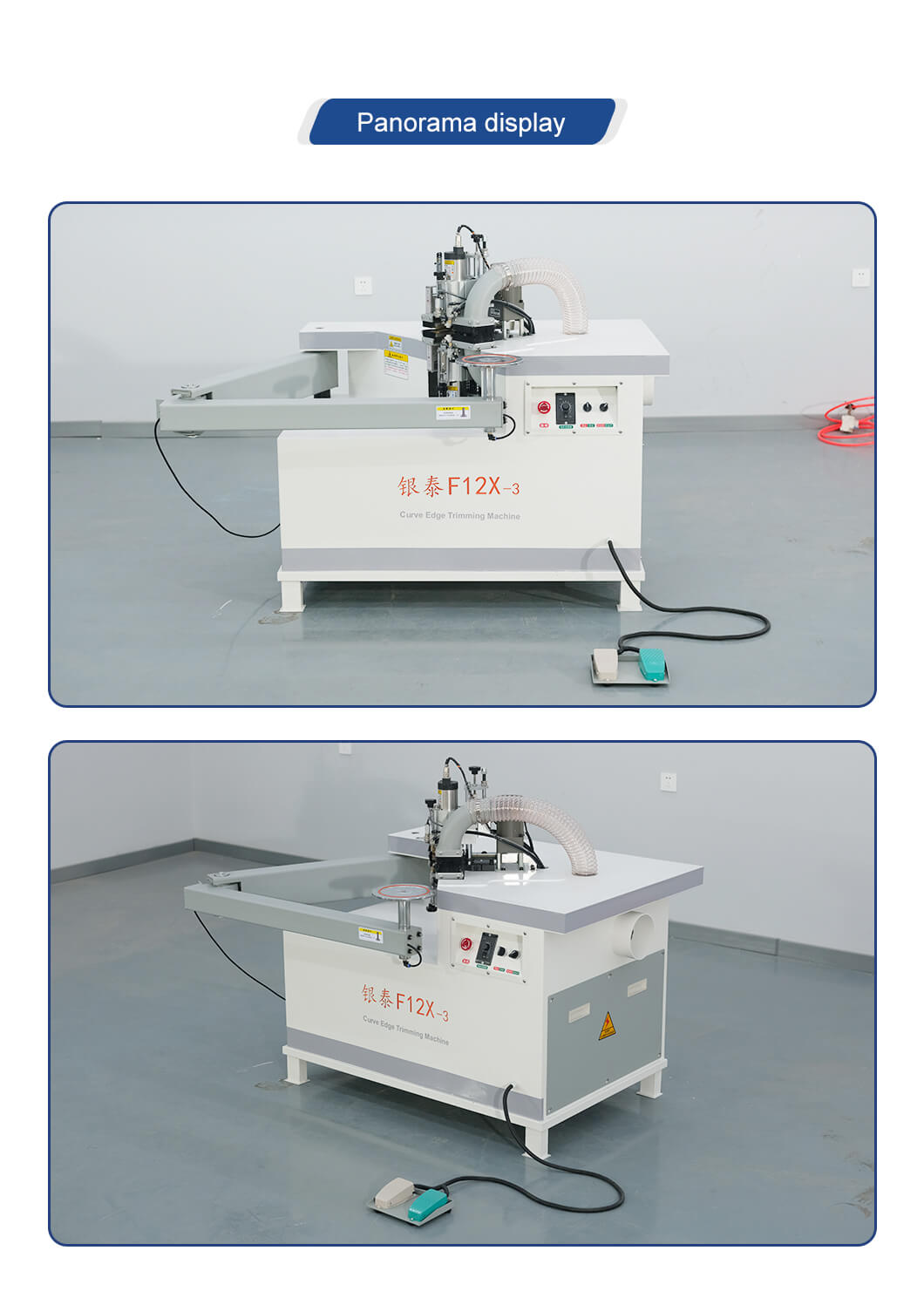

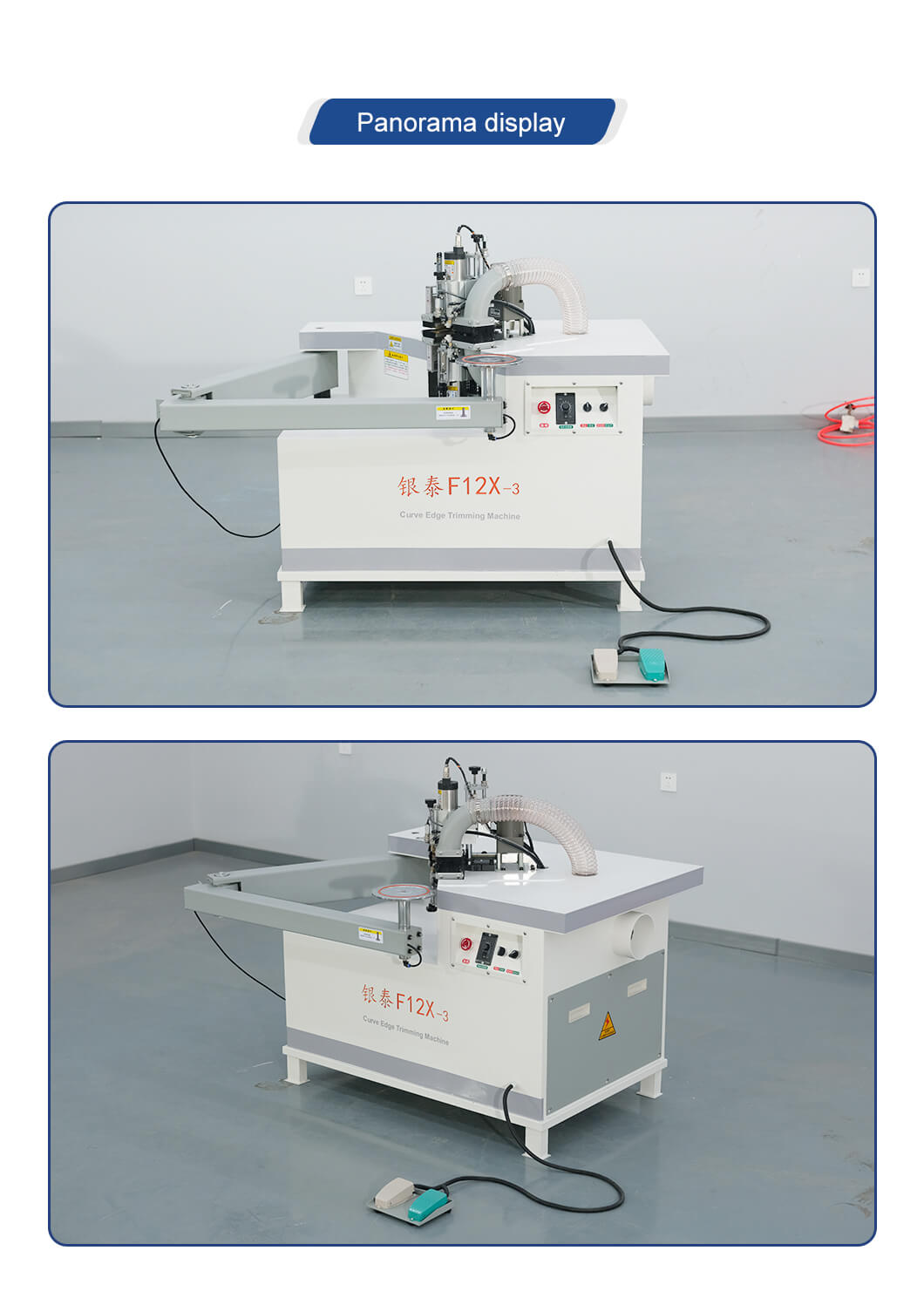

F12X-3 Curve Edge Trimming Machine Features

1.The standard small workpiece platform facilitates trimming of small plates (both large and small plates can be done in one machine).

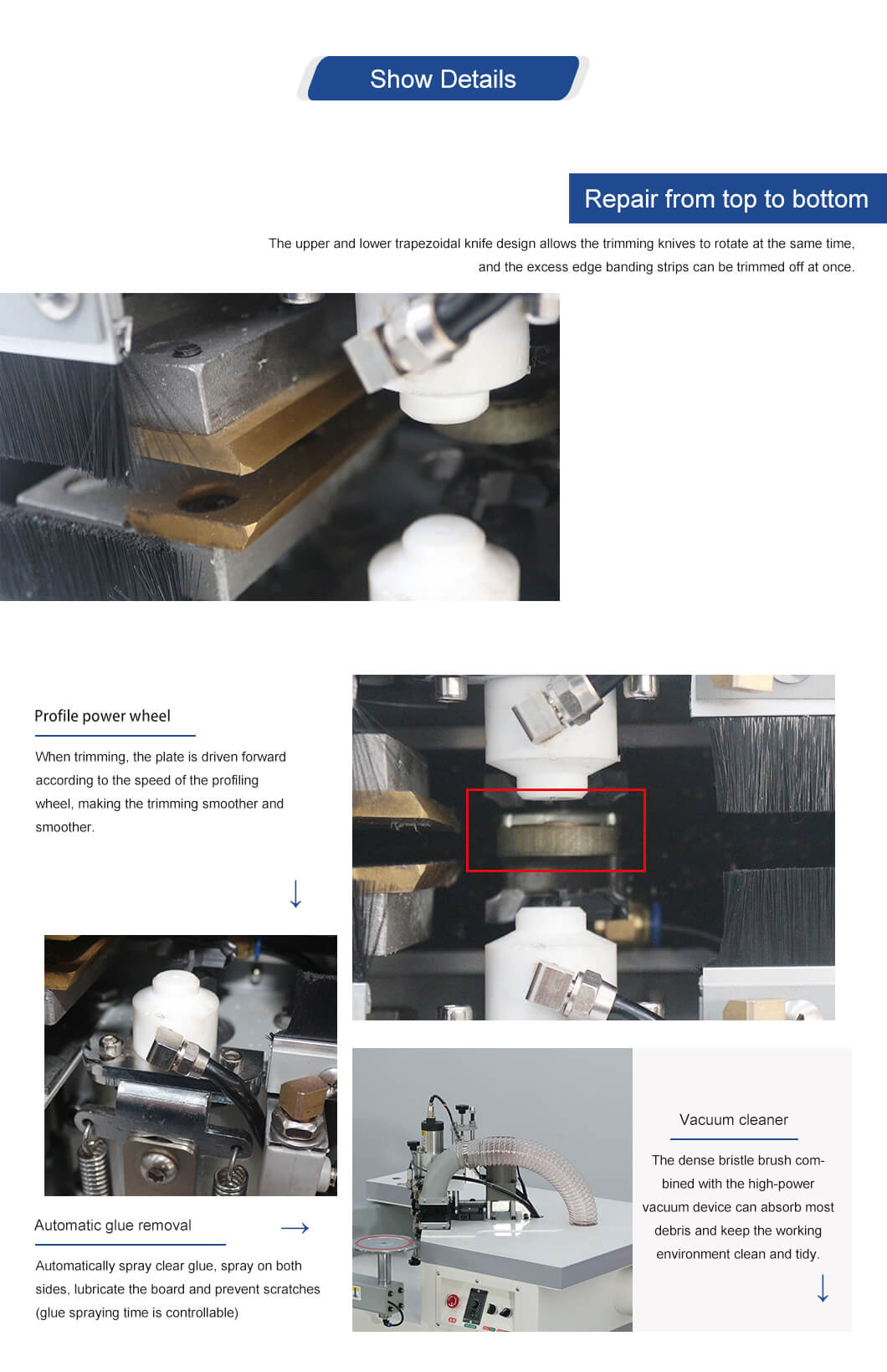

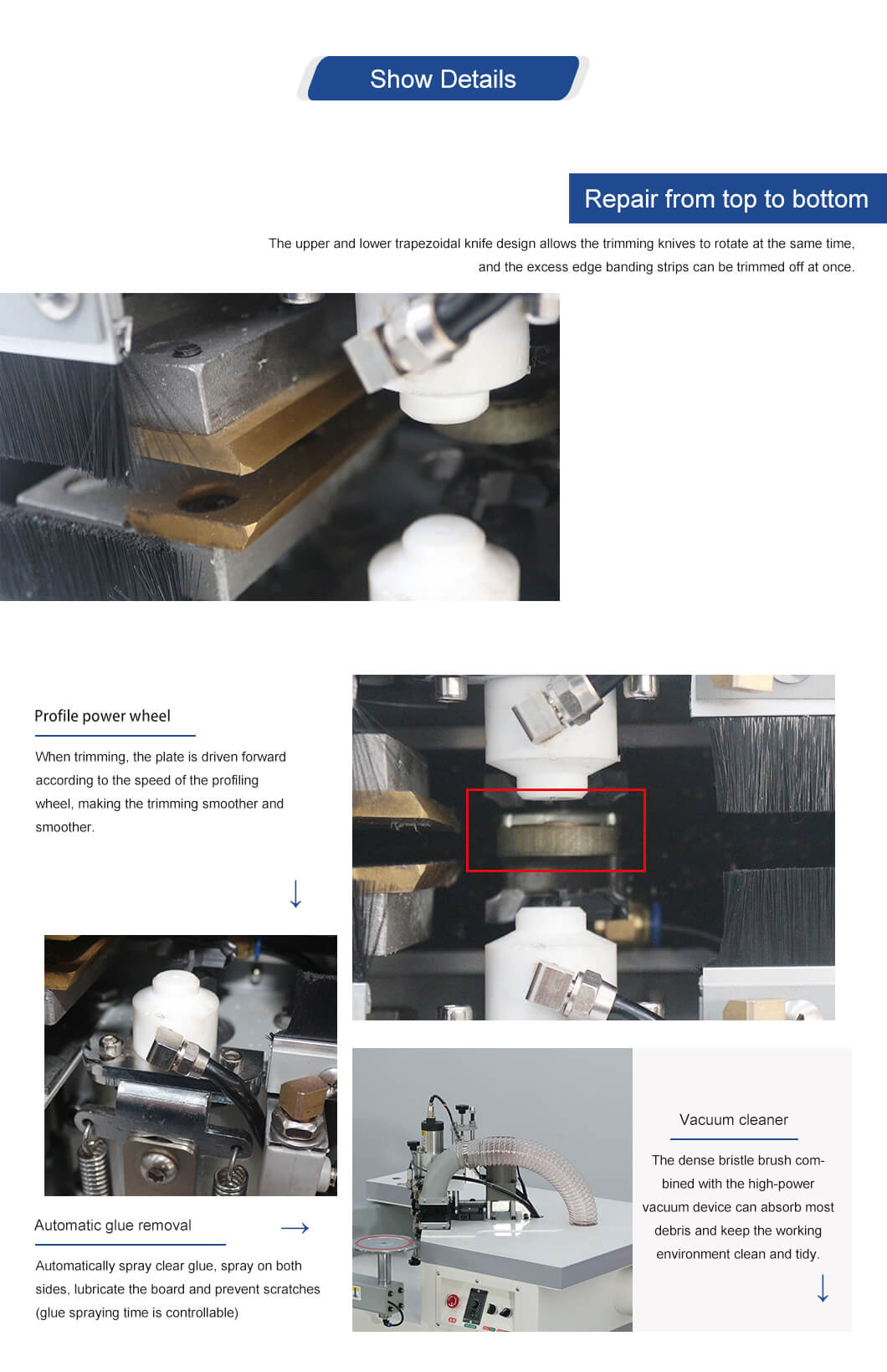

2.The upper and lower sides are trimmed together, and the trimming knife rotates at the same time, and the excess edge banding strips on the upper and lower sides are trimmed off at one time.

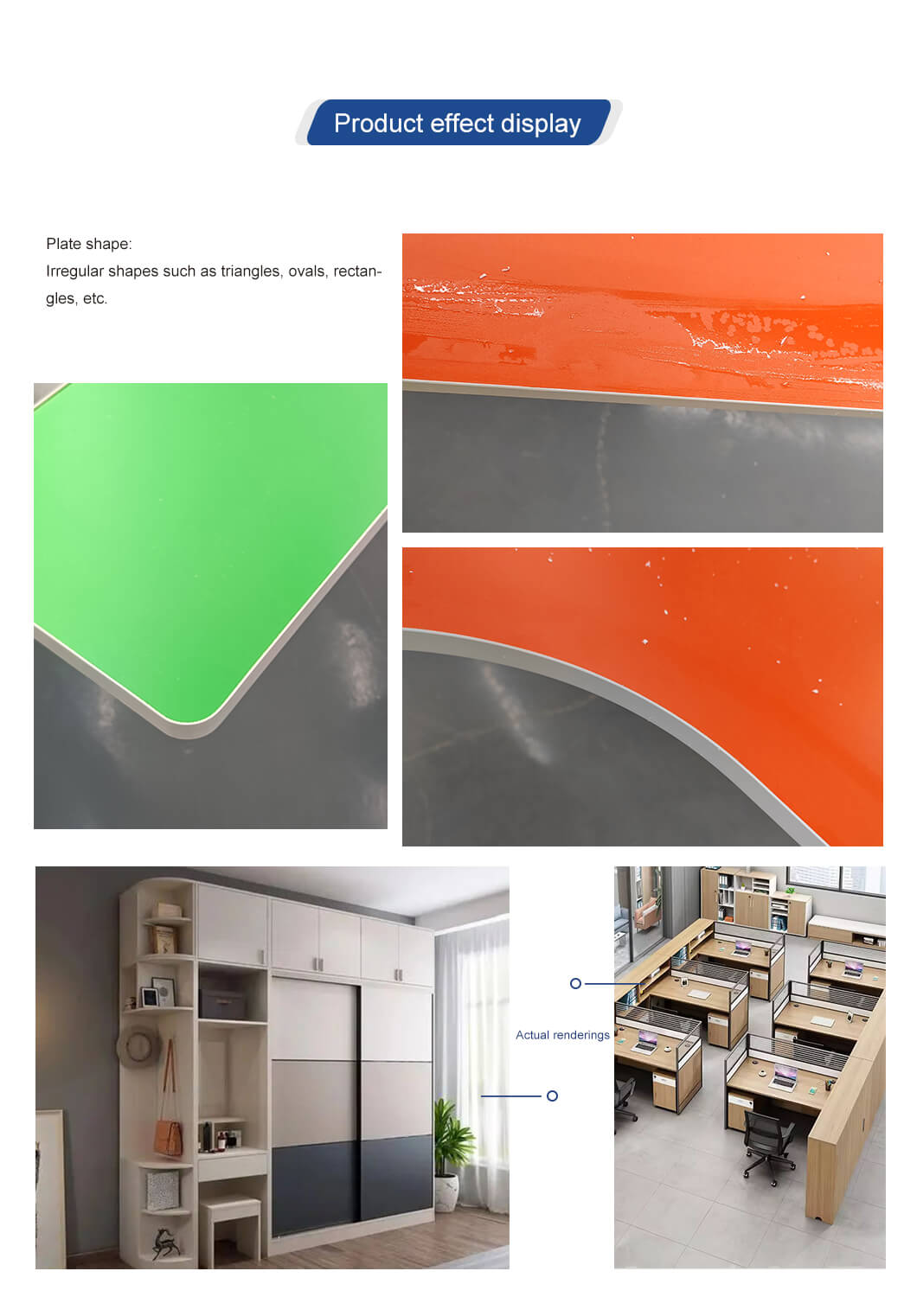

3.Automatic glue clearing, automatic spraying of glue clearing agent, double-sided spraying to prevent blades and plates from being stuck with glue, which affects the trimming effect, lubricates the plates, and prevents scratches (the glue spraying time is controllable).

4.Scrape along with the movement. After the trimming is completed, the excess edge strips and glue lines are scraped off flatly. The double-sided trapezoid design can be trimmed and the utilization rate is high (trimming, clearing glue, and scraping the edges are formed in one go).

5.Photoelectric induction (start-stop switch), automatically senses the plate for 5 seconds, and automatically stops if the plate cannot be sensed, protecting worker safety and saving energy.

6.No need to adjust the plate thickness, quickly adapt to different plate thicknesses (14-70cm) less than 14mm, customized profiling plywood.

F12X-3 Curve Edge Trimming Machine Paramenters

| | |

| | |

| | |

| | |

Thickness of edge banding | |

| | <14mm(one-sided trimming)14-70mm(trimming up and down) |

| | |

| | |

| | |

| | |

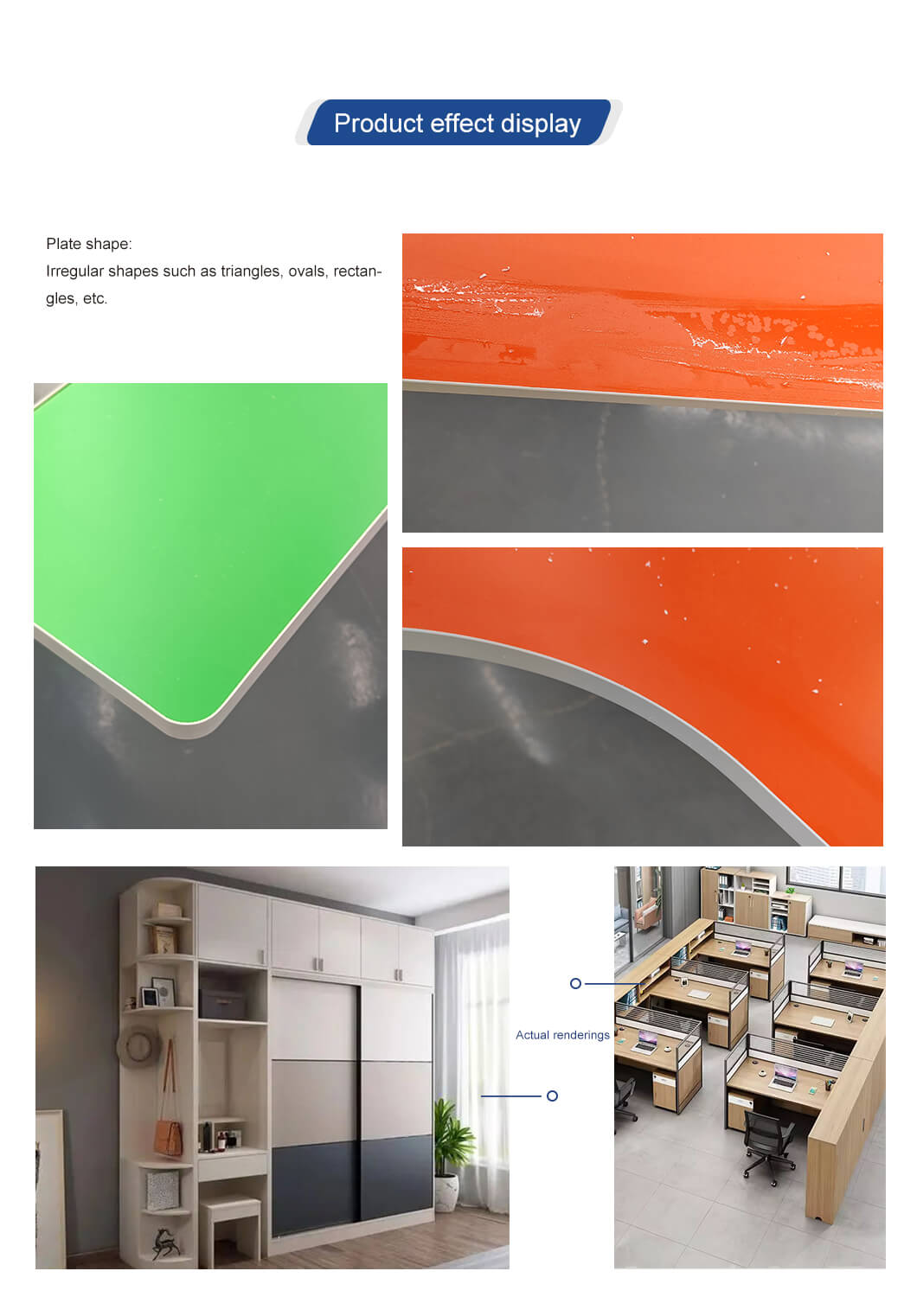

F12X-3 Curve Edge Trimming Machine Details Images