Aluminum-wood Universal Straight Edge Banding Machine Features

1.Pre-milling: Double diamond cutter head and double motor structure, two reverse cutter heads, no edge collapse during milling, no burrs on the board surface, simple and convenient adjustment, dust blowing device on the board surface after pre-milling.

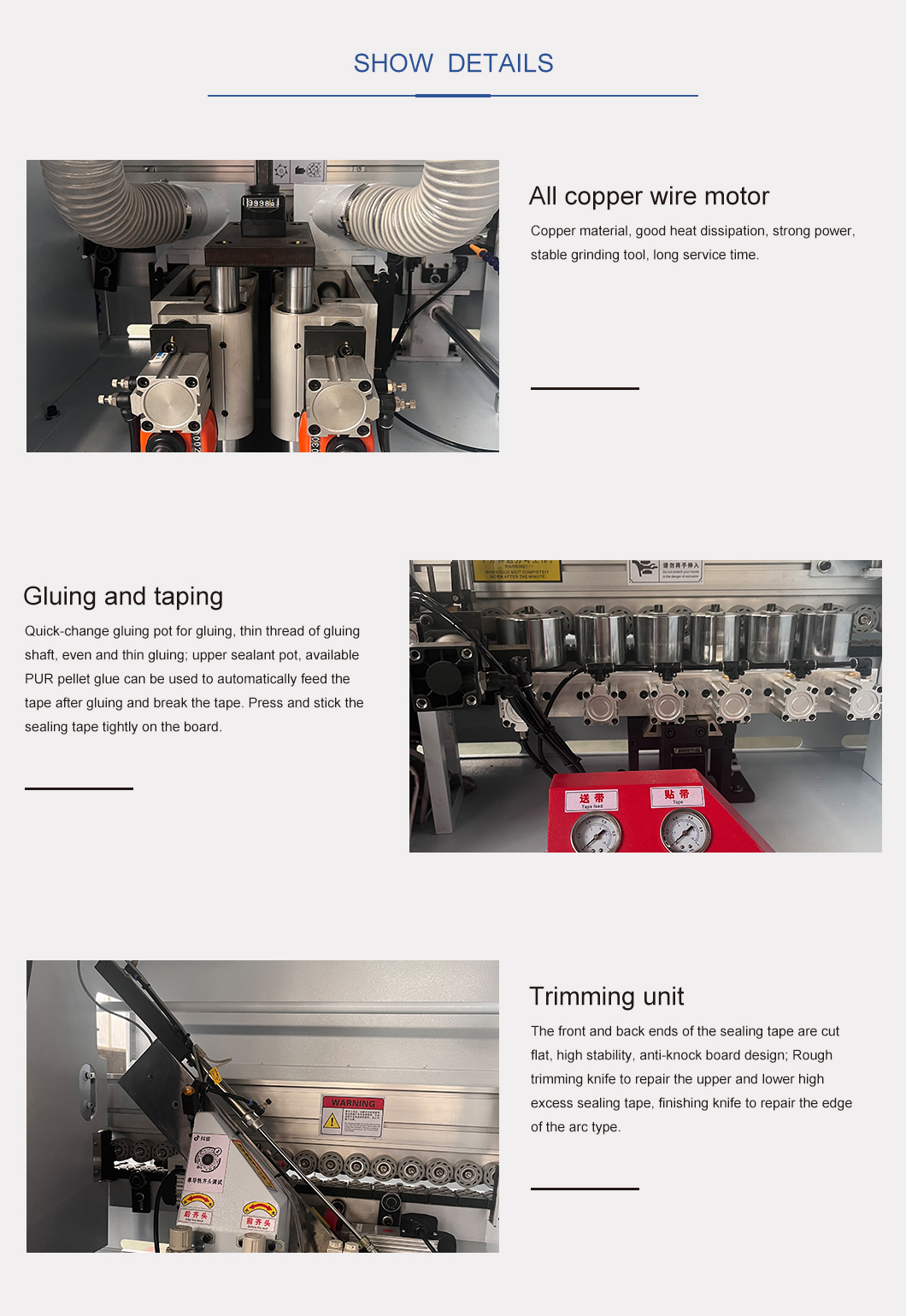

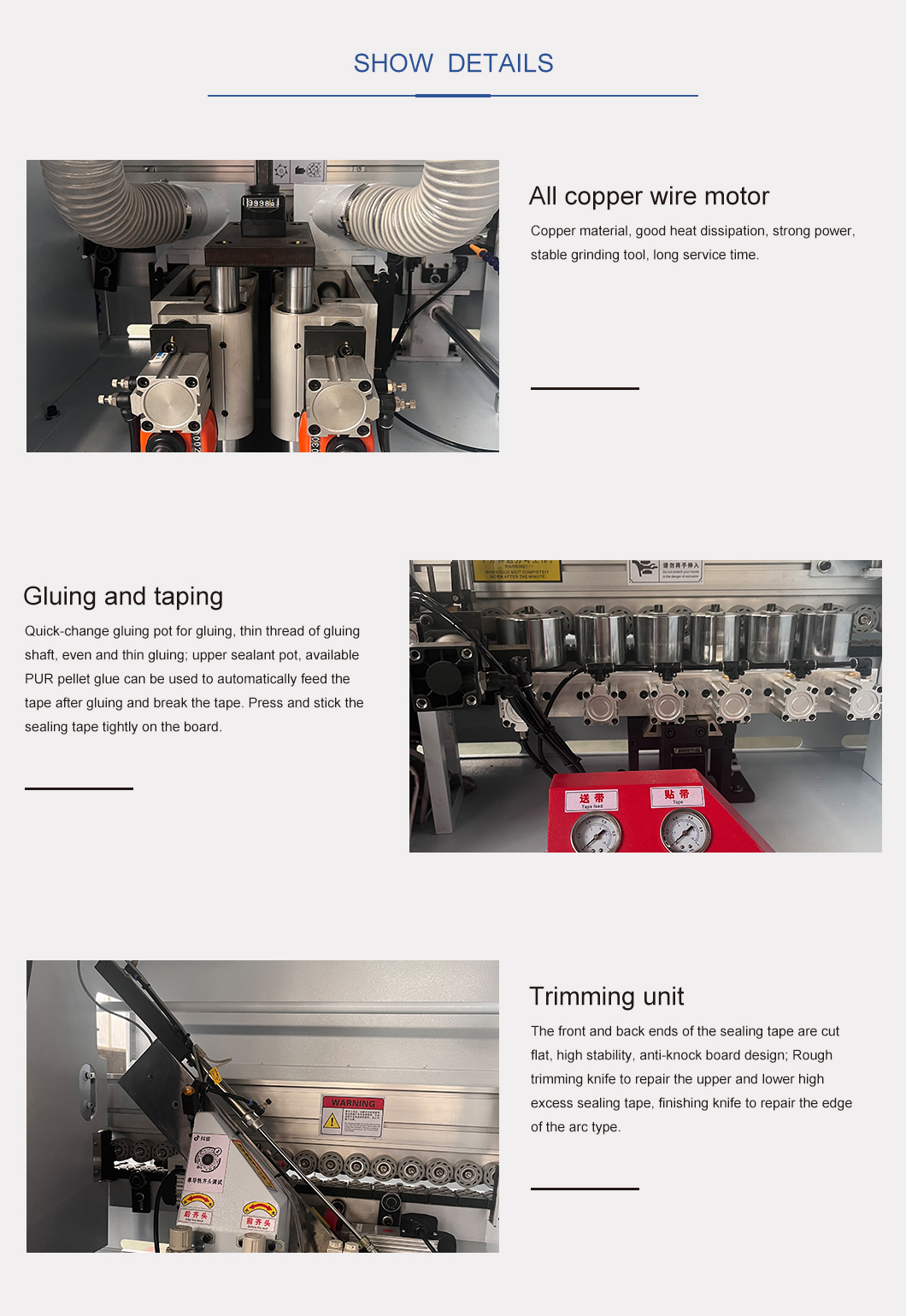

2.Gluing and taping: Gluing with quick-change glue pot, the glue shaft has fine threads, and the glue is applied evenly and thinly; the sealing glue pot is placed on top, and the PUR granular glue can be used for glue application and automatic tape feeding and tape breaking. Pressing presses the edge banding tape tightly onto the board.

3.Cut edge, rough trim, and fine trim: Cut the edge bands flat at both ends, with high stability and anti-knock design; the rough trimming knife trims the excess edge bands above and below, and the fine trimming knife trims the edge into an arc shape.

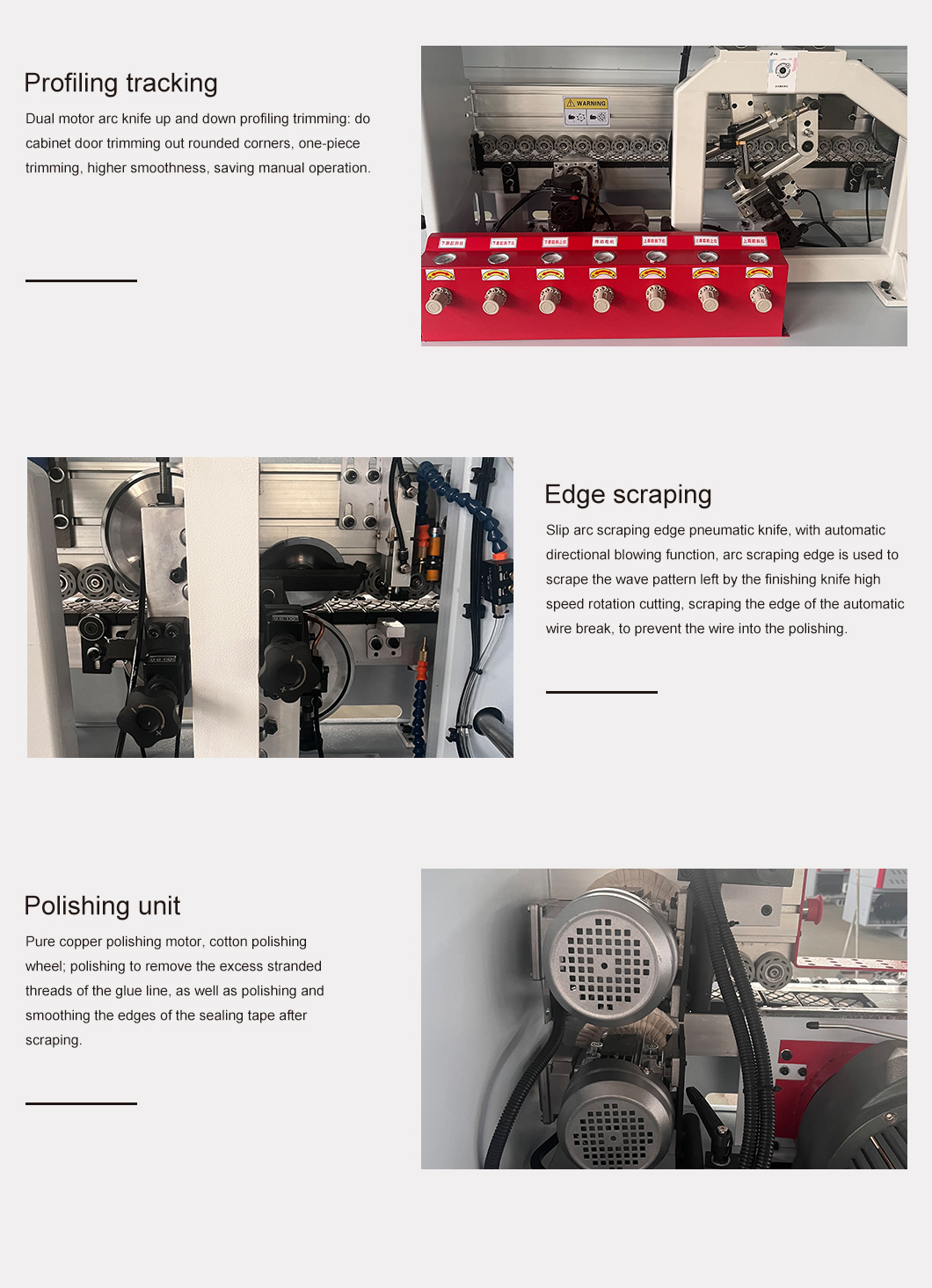

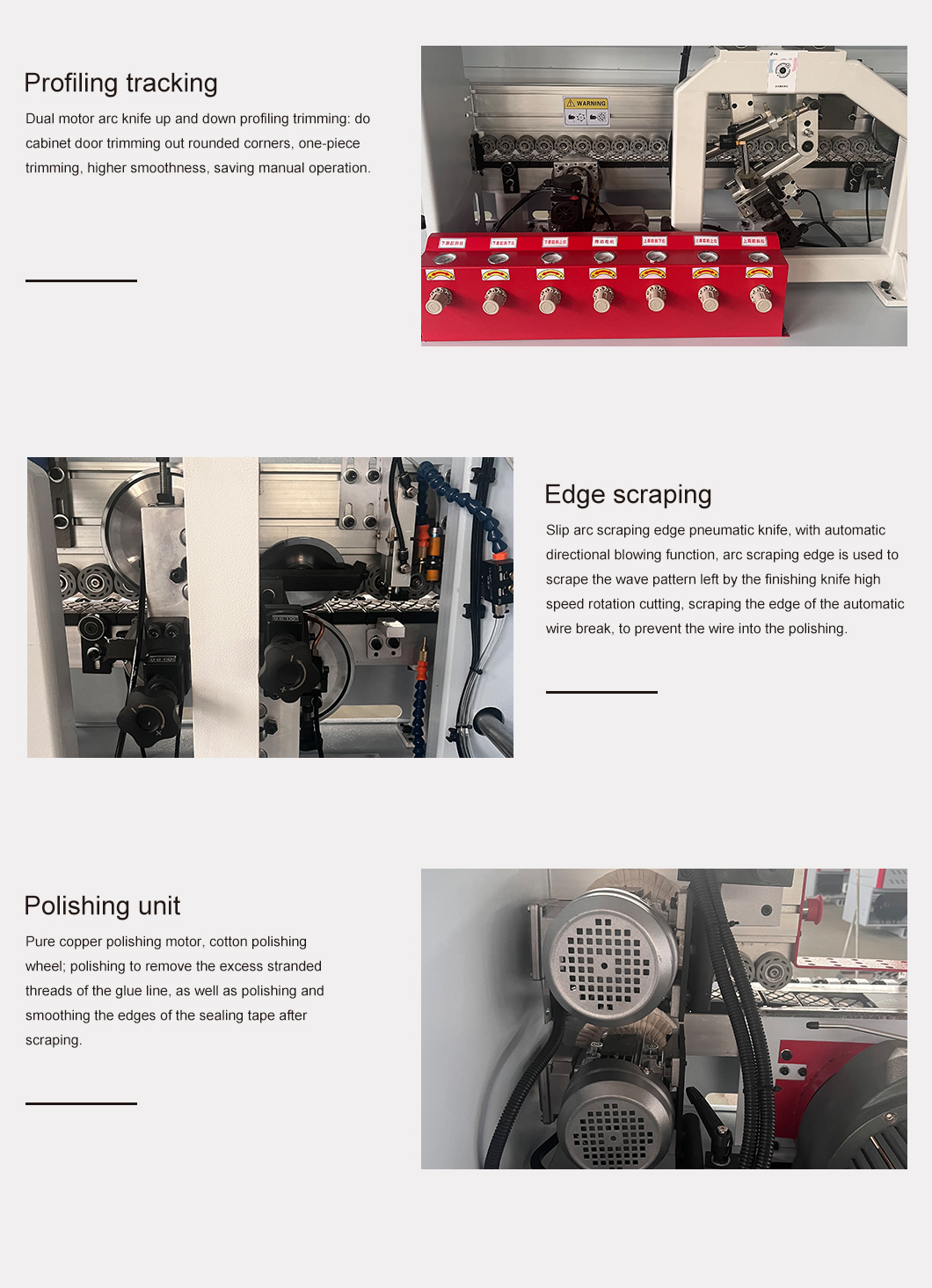

4.Profiling and tracking: Double motor arc knife up and down profiling and trimming: make rounded corners of cabinet doors, integrated trimming, higher smoothness, saving manual operation.

5.Scraping edge: Smooth arc scraping edge pneumatic knife adjustment, with automatic directional wire blowing function, arc scraping edge is used to flatten the wavy pattern left by the high-speed rotary cutting of the finishing knife, and the wire will be automatically cut off after scraping to prevent the wire from entering the polishing.

6.Pneumatic knife adjustment: When changing edge banding of different thicknesses/types, there is no need to manually adjust the distance between the finishing and scraping edges and the board. The machine automatically adjusts to the appropriate position.

7.Cleaning device: spray separation agent on the upper and lower sides of the board before gluing to prevent overflow glue from sticking to the board surface; spray cleaning agent on the glue line before polishing to make the polished glue line cleaner.

8.Polishing: Pure copper polishing motor, cotton polishing wheel; polishing to remove excess twisted wires of the glue wire, and polishing the edge of the edge banding after smooth scraping.

Aluminum-wood Universal Straight Edge Banding Machine Parameters

Total power

| 12.7KW | Thickness of edge banding | 0.4-3mm |

Power supply | 380V 50Hz | Edge banding speed | (18-20-22)m/min |

Air pressure | 0.7-0.9MPa | Plastic box heating power | 1.8kw |

Workpiece length | ≥80mm | Plastic box transmission power | 0.75kw |

| Workpiece width | ≥150mm | Panel thermal power | 0.3KW |

Workpiece thickness | ≤55mm | Transmission motor power

| 3.7kw

|

These parameters ensure that the 388 fully automatic edge banding machine can adapt to wood processing operations of different scales and requirements, while ensuring the efficiency and quality of the edge banding process.

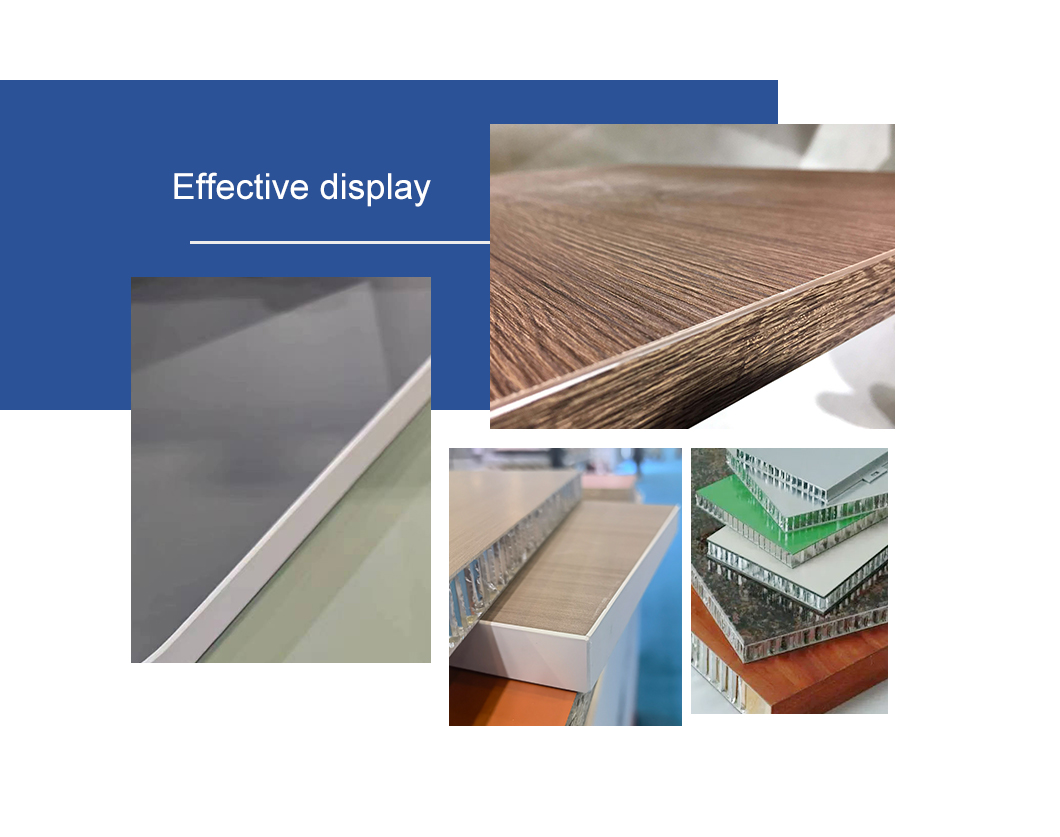

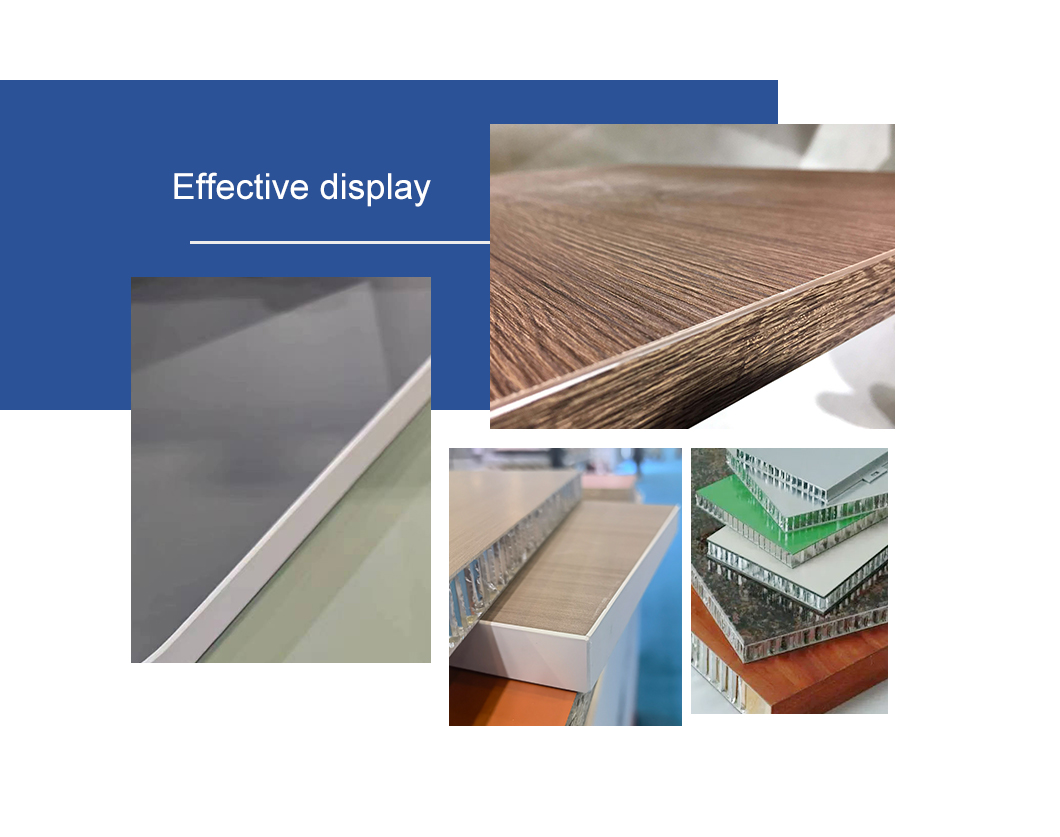

Aluminum-wood Universal Straight Edge Banding Machine Details